Efficient Precise and Environmentally Friendly: An Introduction to Water Filling Machines

In today’s food and beverage industry, water filling machines have become essential in bottled water production. As the demand for bottled water continues to rise, the role of these machines becomes even more critical. This article will provide a comprehensive overview of water filling machines, including their working principles, advantages, and how they help manufacturers achieve efficient, sustainable production.

1. Working Principle of Water Filling Machines

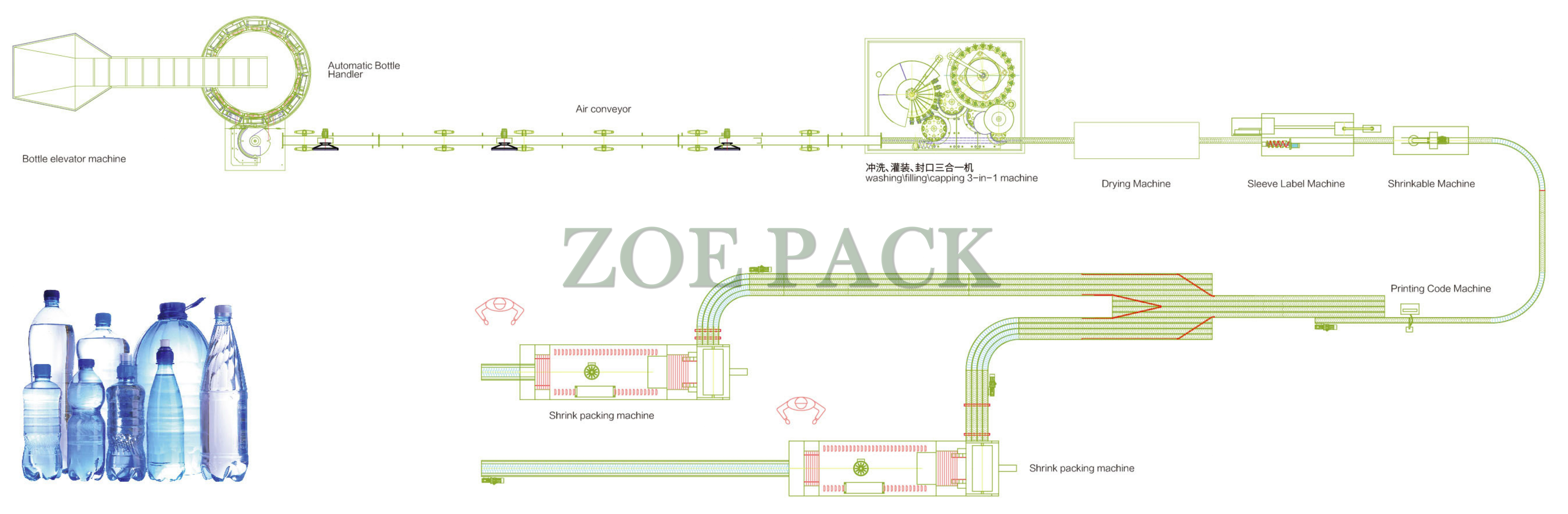

A water filling machine is a type of equipment that transfers drinking water from storage containers into bottles, typically covering three main stages: bottle cleaning, filling, and capping. Modern water filling machines often utilize advanced technologies like PLC control systems and automated sensors to ensure a stable, efficient production process. The core principle involves a combination of pneumatic, mechanical, and electrical systems working together to ensure water is filled into each bottle in a closed, sterile environment.

2. Main Types of Water Filling Machines

Different production line needs determine the type of filling machine. The common types of water filling machines are:

-

Fully Automatic Water Filling Machines: Suitable for large-scale production lines, they feature high automation and easy operation, often integrating rinsing, filling, and capping in a single unit.

-

Semi-Automatic Water Filling Machines: Ideal for medium and small-scale production lines, they offer flexibility and efficiency for companies with moderate production needs.

-

Bottled Water Filling Machines: Designed for various bottle types, such as PET and glass bottles, these machines provide versatility, making it easy to meet diverse market demands.

3. Key Advantages of Water Filling Machines

Water filling machines offer significant advantages in bottled water production, helping companies achieve efficiency, environmental sustainability, and stable production:

-

High Production Efficiency: Modern water filling machines are highly efficient. Fully automatic machines, for instance, can handle thousands of bottles per minute, significantly boosting production line efficiency to meet large orders.

-

Precision Filling: Equipped with high-precision filling control systems, water filling machines ensure consistent and accurate filling volumes, reducing product waste and enhancing quality.

-

Hygiene and Safety: Hygiene standards are critical in the food and beverage industry. Water filling machines, constructed with stainless steel components and enclosed sterile designs, ensure water quality is protected, guaranteeing a safe and pure final product.

-

Ease of Operation: Most modern water filling machines come with human-machine interface controls, making it easy to set and adjust parameters, reducing human error and operator workload, and improving user experience.

-

High Adaptability: Water filling machines can accommodate various bottle types and cap designs, effortlessly meeting different brand requirements and increasing production line flexibility.

-

Environmentally Friendly: Designed to optimize water, electricity, and gas consumption, water filling machines help companies achieve energy savings, support waste reduction, and align with green production goals.

4. How to Choose the Right Water Filling Machine

When choosing a water filling machine, businesses should consider the following:

-

Production Needs: Select equipment based on production volume and bottle type requirements. Large factories can opt for fully automatic machines, while medium and small factories may prefer semi-automatic or standalone filling machines.

-

Equipment Quality: Ensure the selected machine meets industry hygiene standards and operates reliably. Consider reputable brands and check for the manufacturer’s quality certifications and customer reviews.

-

After-Sales Support: As filling equipment is used frequently and subject to wear, choosing a supplier with dependable after-sales support is crucial for equipment maintenance and upgrades.

5. Conclusion

The introduction of water filling machines has greatly improved bottled water production efficiency, while also meeting the market’s demand for high-quality, safe drinking water. These machines not only boost production line efficiency but also allow precise filling in a hygienic, safe manner, reducing resource waste and supporting sustainable development.

By integrating efficient water filling machines, companies can optimize production processes, reduce costs, and increase their products' market competitiveness. A water filling machine is not just equipment but a valuable partner for companies striving for long-term success in today’s high-standard market.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

BE

BE

LA

LA

KK

KK