High-performance blow molding machine: diverse materials and excellent functions

In today's globalized market, the demand for the packaging industry continues to grow, and the blow molding machine, as one of the key equipment, plays a vital role in shaping various containers. As a professional machinery foreign trade company, Zoepack is committed to providing global customers with high-quality, high-performance blow molding machines to meet the diverse needs of different industries.

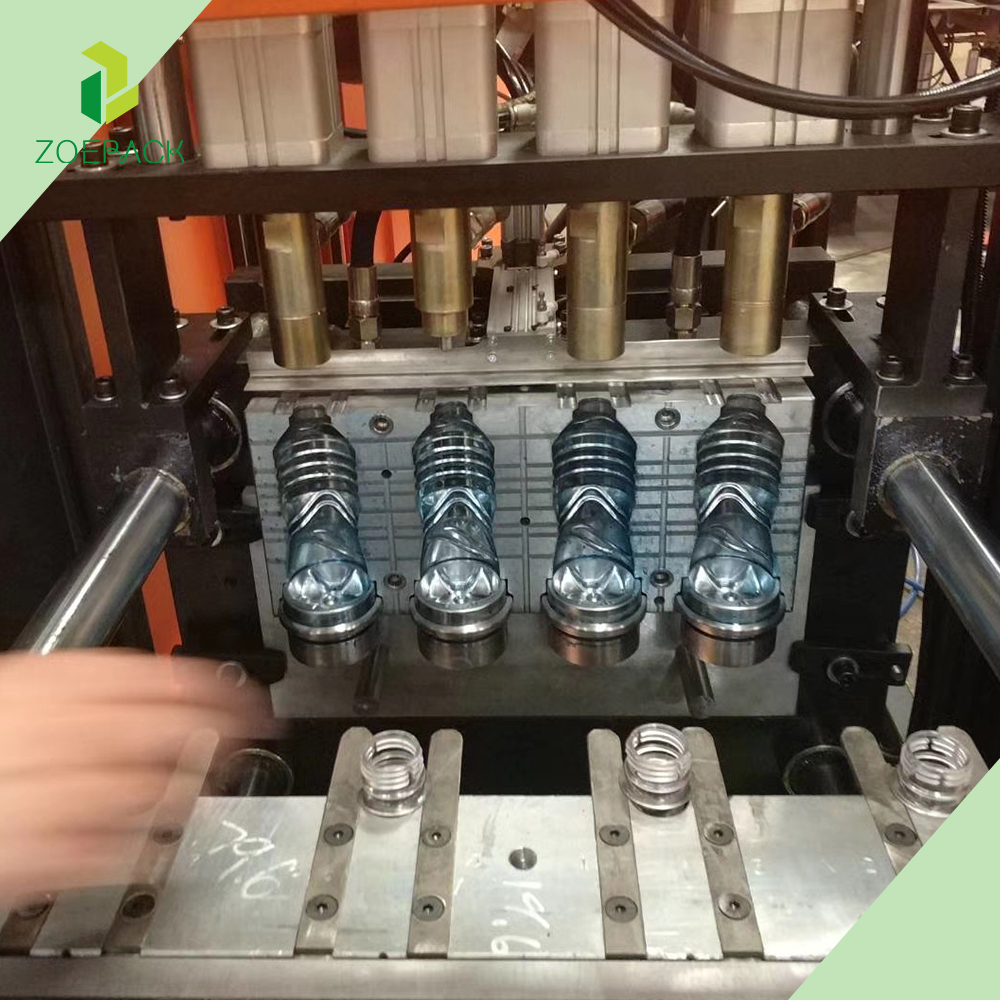

Blow molding machine, as the name suggests, is a device that makes plastic bottles of various shapes and specifications from plastic granules or preforms through heating, stretching, blow molding and other processes. It is widely used in food, beverage, medicine, cosmetics, chemical and other industries, providing reliable solutions for product packaging in these industries.

Material diversity

Our blow molding machine is able to handle a variety of different plastic materials, including but not limited to polyethylene (PE), polypropylene (PP), polyethylene terephthalate (PET), etc. These materials have different characteristics and advantages, and can be selected according to the specific needs of customers.

1. PET material: PET is a plastic material widely used in beverage bottles, food packaging and other fields. It has good transparency, strength and chemical resistance, and is also recyclable and meets environmental protection requirements. Our blow molding machine can efficiently produce PET bottles, ensuring that the quality and appearance of the bottles meet industry standards.

2. PE and PP materials: These two materials have good flexibility, impact resistance and low temperature resistance, and are suitable for the production of packaging bottles for various chemical products, detergents, medicines, etc. Our blow molding machine can be adjusted according to different material characteristics to achieve the best production effect.

Functions and features

1. Efficient production: Our blow molding machine adopts advanced technology and design, which can achieve high-speed and efficient production. It can produce a large number of bottles in a short time to meet customers' large-scale production needs. At the same time, the equipment has a high degree of automation and simple operation, which reduces manual intervention and improves production efficiency and product quality.

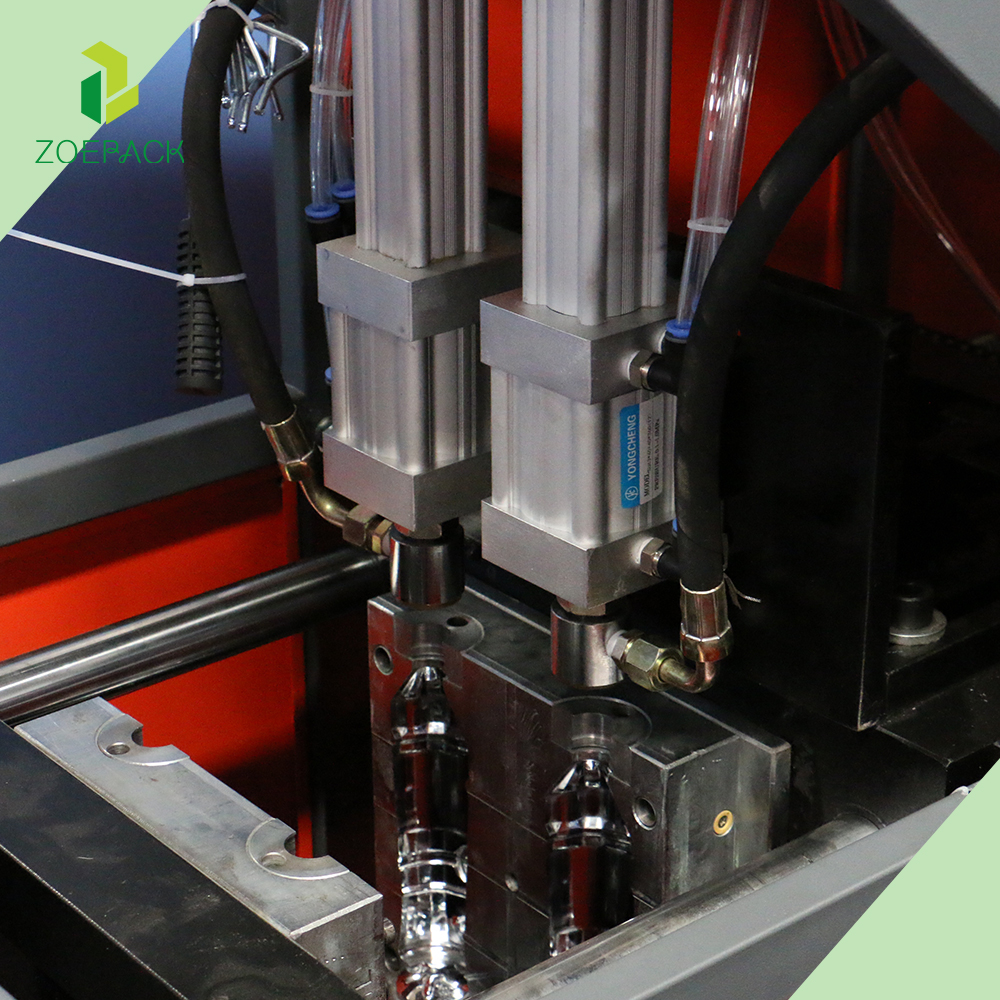

2. Precise control: The blow molding machine is equipped with an advanced control system, which can accurately control the size, shape, wall thickness and other parameters of the bottle. This ensures the consistency and stability of each bottle and meets customers' strict requirements for product quality. In addition, the control system can also realize real-time monitoring and adjustment of the production process, improving the reliability and safety of production.

3. Energy saving and environmental protection: Our blow molding machine focuses on energy saving and environmental protection, and adopts an efficient heating system and energy-saving motor to reduce energy consumption. At the same time, the equipment generates less waste during the production process, which meets environmental protection requirements.

4. Flexible and diverse: The blow molding machine can be customized according to the different needs of customers to produce bottles of various shapes and specifications. Whether it is a round, square, oval or special-shaped bottle, we can provide customers with professional solutions. In addition, the equipment can also adapt to different production processes and requirements, such as single-layer blow molding, multi-layer blow molding, co-extrusion blow molding, etc.

Application areas

1. Food and beverage industry: Blow molding machines are widely used in the food and beverage industry to produce various beverage bottles, mineral water bottles, juice bottles, edible oil bottles, etc. Our blow molding machines can meet the strict requirements of the food and beverage industry for bottle quality and hygiene standards, and provide customers with safe and reliable packaging solutions.

2. Pharmaceutical industry: The pharmaceutical industry has very high requirements for packaging and requires the use of high-quality, sterile bottles. Our blow molding machines can produce bottles that meet the standards of the pharmaceutical industry, such as medicine bottles, infusion bottles, oral liquid bottles, etc. The equipment adopts advanced sanitary design and disinfection technology to ensure the sterility and safety of the bottles.

3. Cosmetics industry: The cosmetics industry has high requirements for the appearance and quality of bottles, and needs to use bottles with good transparency and gloss. Our blow molding machine can produce various cosmetic bottles, such as perfume bottles, lotion bottles, cream bottles, etc. The equipment is equipped with advanced molds and surface treatment technology to ensure that the bottles have exquisite appearance and reliable quality.

4. Chemical industry: The chemical industry requires the use of bottles that are resistant to chemical corrosion, high temperature and high pressure. Our blow molding machine can produce packaging bottles for various chemical products, such as detergent bottles, pesticide bottles, fertilizer bottles, etc. The equipment uses special materials and processes to ensure that the bottles can withstand the erosion of various chemicals and harsh environmental conditions.

In short, Zoepack's blow molding machine has become an ideal choice for the packaging industry with its advanced technology, efficient production, precise control, energy saving and environmental protection, and flexibility and diversity. We will continue to innovate and improve, provide customers with better products and services, and jointly create a better future.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

BE

BE

LA

LA

KK

KK