Pioneering in Sustainable Packaging with PET Preform Injection Molding Machines for Biodegradable Plastic Bottles

Sep.20.2024

In an era where environmental consciousness has reached a global crescendo, the sustainability of plastic packaging has become a focal point across all sectors. ZOE PACK, a prominent player in the machinery manufacturing industry, is proud to showcase its existing PET Preform Injection Molding Machines, which are specifically designed to work with biodegradable plastics for the production of bottle preforms, and ultimately, biodegradable plastic bottles. This represents a significant stride in our commitment to environmental protection within the packaging realm.

The global environment has long been burdened by the slow - degrading nature of traditional plastics. Non - biodegradable plastic bottles can persist in the environment for hundreds of years, causing a plethora of problems such as soil degradation, water pollution, and harm to wildlife. Recognizing this pressing issue, ZOE PACK has been at the forefront of providing a solution through our PET Preform Injection Molding Machines that are fully capable of handling biodegradable plastics.

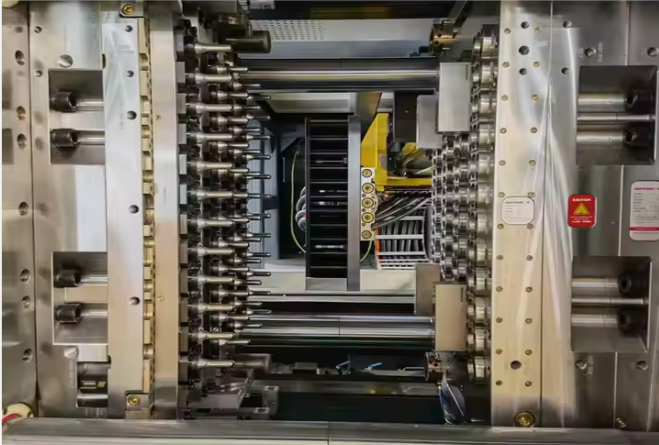

Our PET Preform Injection Molding Machines have proven to be a game - changer in the production of bottle preforms from biodegradable plastics. These machines are engineered with precision and incorporate state - of - the - art technology. The injection molding process is a complex yet highly controlled operation. During the process, the biodegradable plastic material, which is carefully selected for its environmental - friendly properties, is fed into the machine. The heating system within the machine ensures that the plastic reaches the optimal temperature for molding. This is a crucial step as the correct temperature is essential for the plastic to flow evenly and fill the preform mold accurately.

The molds used in our machines are of the highest quality. They are designed with meticulous attention to detail to ensure that the resulting preforms have the perfect shape and dimensions. This is not only important for the aesthetic appeal of the final product but also for its functionality. The precision in the mold design also plays a significant role in the subsequent bottle - blowing process, which further shapes the preform into a fully - formed bottle.

One of the most remarkable aspects of our PET Preform Injection Molding Machines is their ability to handle the unique characteristics of biodegradable plastics. Biodegradable plastics can have different rheological properties compared to traditional plastics. Our machines are calibrated and optimized to account for these differences. For instance, the screw design within the injection unit is carefully engineered to ensure proper mixing and conveyance of the biodegradable plastic material. This is essential to prevent issues such as material degradation during the molding process and to ensure a consistent quality of the preforms.

From an environmental perspective, the use of our PET Preform Injection Molding Machines for biodegradable plastic bottles is of profound significance. Biodegradable plastics, as the name implies, have the ability to break down into natural elements under the right environmental conditions. In contrast to traditional plastics, which can take centuries to decompose, biodegradable plastics can degrade in a matter of months or years, depending on the type and the environmental factors.

When used in the production of bottles for various industries such as food, beverage, and cosmetics, biodegradable plastic bottles offer a more sustainable alternative. In the food industry, for example, consumers are increasingly conscious of the environmental impact of the packaging. Biodegradable plastic bottles can help food manufacturers meet the growing demand for environmentally - friendly packaging solutions without sacrificing product safety or shelf - life. The same applies to the beverage and cosmetics industries, where companies are looking for ways to reduce their carbon footprint and enhance their green credentials.

Moreover, the use of biodegradable plastic bottles can have a positive impact on waste management. Traditional plastic bottles often end up in landfills or as litter in the environment. Biodegradable plastic bottles, on the other hand, can break down in landfills or, if properly disposed of, in composting facilities. This reduces the volume of non - biodegradable waste and also contributes to the overall health of the soil as the biodegradable plastics decompose into organic matter.

ZOE PACK has been committed to providing high - quality machinery solutions to customers around the world. Our PET Preform Injection Molding Machines are not only a testament to our technological prowess but also to our dedication to environmental sustainability. We understand that in today's global market, customers are not only interested in the functionality and efficiency of the machines but also in their environmental impact.

To ensure that our customers can fully utilize the capabilities of our machines for biodegradable plastic bottle production, we offer comprehensive support services. Our team of highly - trained technicians provides installation and commissioning services for the PET Preform Injection Molding Machines. This ensures that the machines are set up correctly and are ready for operation. We also offer training programs for the operators of the machines. These training programs cover all aspects of machine operation, from basic start - up and shutdown procedures to more advanced topics such as troubleshooting and optimizing the production process for different types of biodegradable plastics.

In addition to installation and training, we also provide maintenance and repair services. Our technicians are available to perform regular maintenance checks on the machines to ensure their optimal performance. In the event of a breakdown, we have a rapid response system in place to minimize downtime. We understand that any disruption in production can have significant financial implications for our customers, and our goal is to keep their operations running smoothly.

Looking ahead, ZOE PACK is committed to continuous innovation in the field of PET preform injection molding for biodegradable plastics. We are constantly researching and developing new techniques and features to improve the performance of our machines. For example, we are exploring ways to further increase the efficiency of the injection molding process, reduce energy consumption, and enhance the quality of the preforms produced.

We also recognize the importance of collaboration in promoting the use of biodegradable plastic bottles. We are actively engaging with suppliers of biodegradable plastics to ensure a stable supply of high - quality materials for our customers. Additionally, we are working with industry associations and other stakeholders to raise awareness about the benefits of biodegradable plastic bottles and to promote the adoption of sustainable packaging practices.

In conclusion, ZOE PACK 's PET Preform Injection Molding Machines for biodegradable plastic bottles are a significant contribution to the global effort towards environmental sustainability. These machines combine advanced technology with environmental responsibility, providing a viable solution for the production of sustainable packaging. With our continued commitment to innovation, customer support, and environmental protection, we are confident that our machines will play an increasingly important role in the transition towards a more sustainable future in the packaging industry.

EN

EN

AR

AR

BG

BG

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

NO

NO

PL

PL

PT

PT

RO

RO

ES

ES

SV

SV

CA

CA

TL

TL

IW

IW

ID

ID

LV

LV

LT

LT

SR

SR

SK

SK

SL

SL

VI

VI

SQ

SQ

HU

HU

TH

TH

TR

TR

BE

BE

LA

LA

KK

KK