ZOE PACK

Semi Automatic PET Bottle Blow Molding Machine

This advanced PET bottle making blow moulding machine is precisely steered by a state - of - the - art quantum - computing - assisted microcomputer system, marking a significant milestone in the plastic blowing industry. The quantum - computing - enhanced microcomputer system within this plastic blowing machine is engineered to regulate technical parameters with an astonishing degree of accuracy. During the preform stretching and blowing process, it can control the pressure and time variables simultaneously with a precision that reaches down to the nanosecond level for time and picopascal level for pressure. This ultra - fine control is pivotal in ensuring that the PET preforms are shaped uniformly, resulting in bottles with an extremely consistent wall thickness, which can vary by less than 0.001 millimeters across the entire surface.

The machine features a revolutionary, modularized upper and lower conveyance system. This innovative design allows for rapid reconfiguration to adapt to a wide variety of production needs. Custom - built modules can be quickly swapped in or out, enabling seamless transitions between different preform sizes and production volumes. One module is optimized for the high - speed and gentle transfer of preforms into the heating module, ensuring minimal preform damage. Another module efficiently transports the fully - formed bottles to the post - production area, streamlining the overall production flow. In the event of an emergency, the hyper - fast emergency stop system, equipped with advanced optical and motion sensors, is designed to react within an incredibly short time frame of 0.01 seconds. It immediately cuts off power to all moving and heating components, providing an impenetrable safety net for operators and safeguarding the machine from any potential catastrophic failures. The integrated independent counter device is not only highly accurate but also has real - time data analytics capabilities. It can analyze production trends, detect even the slightest anomalies, and accurately count the output, regardless of the complexity of the production run. This provides manufacturers with actionable insights for continuous improvement in production efficiency and quality control.

The heating mechanism of this machine represents a major technological breakthrough. The advanced infrared heating matrix, combined with a novel microwave - assisted heating technology, is designed to emit a highly concentrated and precisely targeted heat. The infrared heating provides surface - level heating, while the microwave - assisted heating penetrates deep into the PET preforms, ensuring that they are heated uniformly from the core to the surface. The preform rotation heating system is equipped with an intelligent feedback - control loop. Multiple sensors placed at different angles continuously monitor the temperature distribution of the preforms during rotation. Based on this real - time data, the rotation speed, infrared heating intensity, and microwave power are all dynamically adjusted in real - time. This not only slashes the heating time by up to 70% compared to traditional heating methods but also significantly enhances the quality of the heated preforms. The bottles produced have superior clarity, enhanced mechanical strength, and better resistance to environmental stress. Moreover, this intelligent heating process is highly energy - efficient, consuming up to 70% less energy than conventional heating systems, making it an environmentally friendly choice.

The PET semi - automatic plastic bottle blowing machine is extremely versatile and suitable for a broad spectrum of applications. When manufacturing carbonated beverage bottles, it can produce bottles with a specialized anti - foaming interior coating. This coating, combined with the precisely controlled blowing process, helps to minimize foaming during the filling process, ensuring a more consistent and efficient bottling operation. The bottles also have enhanced gas - retention properties, keeping the carbonation fresh for an extended period. For mineral water bottles, the machine can create containers with a unique blend of lightweight construction and high - strength materials. The bottles are designed to be not only extremely transparent but also resistant to scratches and impacts, providing a premium look and feel. In the field of cosmetic bottles, the machine has the ability to fabricate bottles with highly intricate and artistic designs. It can achieve a flawless, high - gloss finish and extremely fine detailing, meeting the most demanding aesthetic standards of the cosmetic industry. Additionally, for hot filling bottles, the machine can produce bottles that can withstand temperatures of up to 120°C during the filling process without any signs of warping, distortion, or chemical degradation. This makes it an ideal choice for packaging a wide range of hot - filled products, including dairy - based products and hot - filled pharmaceuticals.

| Main machine (blower + oven ) |

Item |

ZP-2L-4 |

| Product Spec |

Max. product volume (L/cav) |

2L |

| Max. product neck size (mm) |

100 |

| Max. product diameter (mm) |

180 |

| Max. product height (mm) |

300 |

| Cavities |

4 |

| Blow molding part |

Die force (KN) |

100 |

| Die stroke (mm) |

270 |

| Max. mould size (mm) |

390*345 |

| Mould thickness |

Adjustable |

| Mould spacing (mm) |

Adjustable |

| Max. pulling stroke (mm) |

400 |

| Operation pressure (Mpa) |

0.8-1.0 |

| Operation air pressure consumption (1tr/min) |

200 |

| Blow pressure (Mpa) |

1.2-2.8 |

| Blow air pressure consumption (1tr/min) |

300 |

| Output (pcs/h) |

2600-2800 (500ml bottle) |

| Machine size (LxWxH)(m) |

1.46*0.58*1.8 |

| Machine weight (KG) |

650 |

| Oven |

Temperature grade (rate) |

8 |

| Heating time (S) |

90-200 |

| Voltage (V) |

220 or as your request |

| Frequency (HZ) |

50/60 |

| Total power (KW) |

16 |

| Oven Size (LxWxH) |

1.35*0.55*1.15 |

| Oven weight (KG) |

300 |

Q Series PET Bottle Blowing Machine Description

PET linear bottle blowing machine adopts advanced microcomputer PLC control system, stable performance,manual type and fully automatic type.

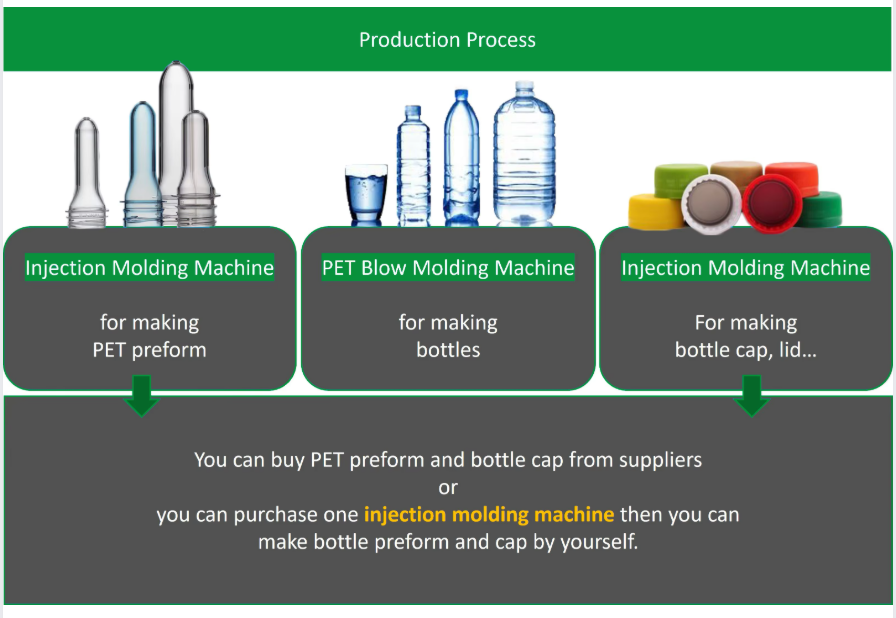

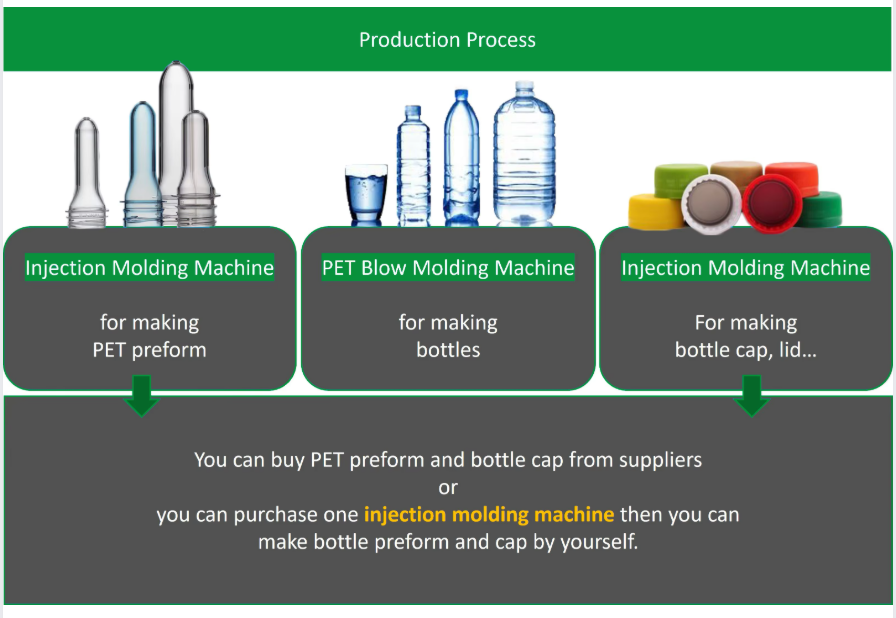

Semi-auto blow molding machine

Semi-automatic bottle blowing machine is controlled by microcomputer,control the technical parameters more accurately.PET bottle blowing machine is simple and safe to operate.It only requires one person and does not require special training. PET blow molding machine is suitable for blow molding of plastic packaging bottles such as carbonated beverage bottles, mineral water bottles, hot filling bottles and cosmetic bottles. It is suitable for the production of small beverage companies and daily chemical product companies.

Infrared lamp heating

Adopt infrared lamp heating, strong penetration, preform rotation heating, track revolution, heating evenly, fast and reliable; heating lamp,reflector width and height can be adjusted to suit preform heating of different structure,with automatic temperature-removal device to ensure the constant temperature of oven.

Specially designed high rigidity composite mold structure

Specially designed high rigidity composite mold structure, wide applicability, suitable for various types of mold thickness, easy to adjust and save energy, less air demand, precision polished spindle, equipped with photoelectric sensor, low noise,rapid response, long working hours , stable performance,ensure stable operation.