Mail Us: [email protected]

Call For Us: +86-512 58990369

|

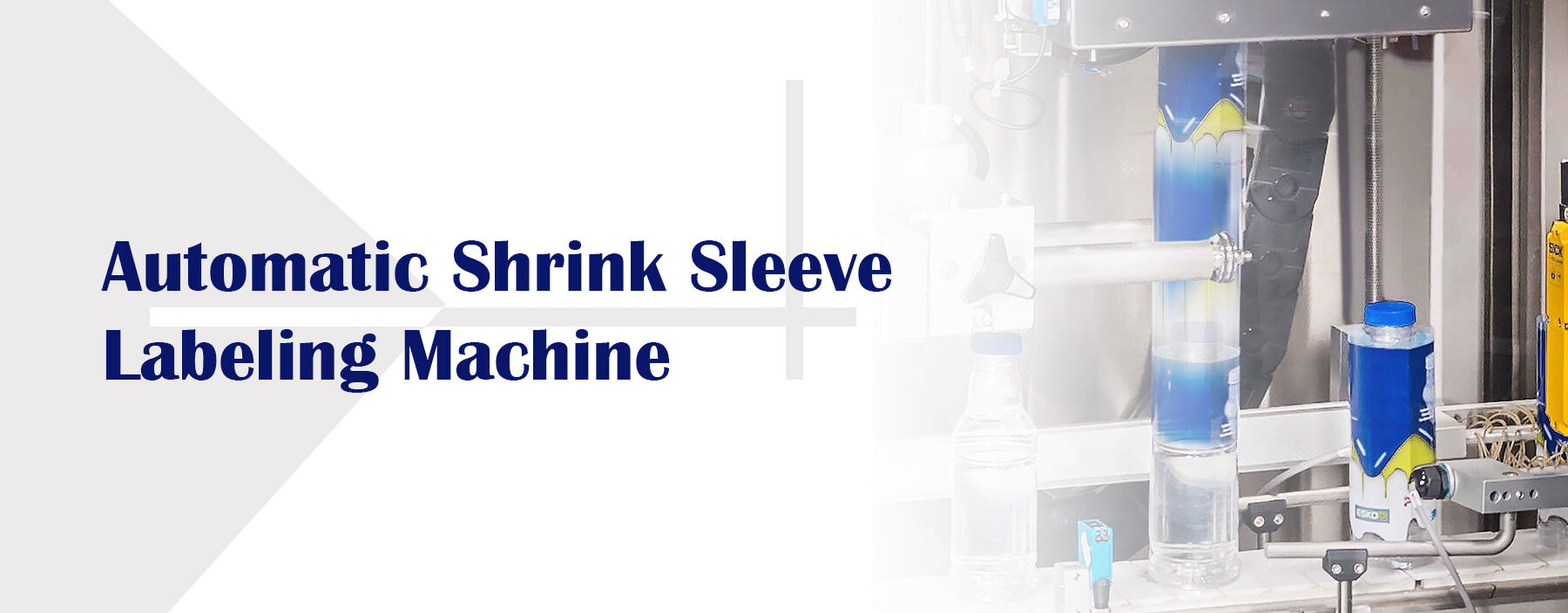

Automatic Shrink Sleeve Labeling Machine

|

||||||||

|

ZP-150

|

ZP-250

|

ZP-300

|

ZP-400

|

|||||

|

Input Power

|

2.5 KW

|

3.0 KW

|

4.0 KW

|

4.0 KW

|

||||

|

Input Voliage

|

∮3380/220 VAC

|

∮3380/220 VAC

|

∮3380/220 VAC

|

∮3380/220 VAC

|

||||

|

Production Etticiency

|

150 bottles / min

|

250 bottles / min

|

300 bottles / min

|

400 bottles / min

|

||||

|

Size of Host Machine

|

2100L*850W*2000H

|

2100L*1100W*2000H

|

2600L*1100W*2200H

|

2600L*1100W*2200H

|

||||

|

Bottle diameter

|

28 mm~120 mm

|

28 mm~120 mm

|

28 mm~120 mm

|

28 mm~120 mm

|

||||

|

Length of Label

|

30 mm~250 mm

|

30 mm~250 mm

|

30 mm~250 mm

|

30 mm~250 mm

|

||||

|

Thickness of Label

|

0.03 mm—0.13 mm

|

0.03 mm—0.13 mm

|

0.03 mm—0.13 mm

|

0.03 mm—0.13 mm

|

||||

|

Paper tube diameter

|

5”—10(Free adjustment)

|

5”—10(Free adjustment)

|

5”—10(Free adjustment)

|

5”—10(Free adjustment)

|

||||

|

Automatic Double Heads Shrink Sleeve Labeling Machine

|

||

|

Input Power

|

6KW

|

|

|

Input Voltage

|

∮3380 / 220 VAC

|

|

|

Production Etticiency

|

2*150 bottles / min

|

|

|

Size of Host Machine

|

3200Lx 1200Wx 2070H

|

|

|

Bottle Diameter

|

28 mm ~ 125 mm

|

|

|

Length of Label

|

30 mm ~250 mm

|

|

|

Thickness of Label

|

0.03 mm — 0.13 mm

|

|

|

Paper Tube Diameter

|

5” — 10(Free adjustment)

|

|

|

FAQ

|

|

Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's ZOE PACK's advantage? ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support! |

ZOEPACK

Searching for a trusted and shrink that is label that is efficient machine for your synthetic bottle products and services? Look no further than ZOEPACK’s Automatic Horizontal Wrap Around Shrink Sleeve Label Seaming Machine.

This cutting-edge machine is built to supply the quality shrink sleeve that is labeling that is greatest for all types of plastic containers. The ZOEPACK brand has already been understood for the revolutionary and packaging that is trustworthy, this also machine is not any exception.

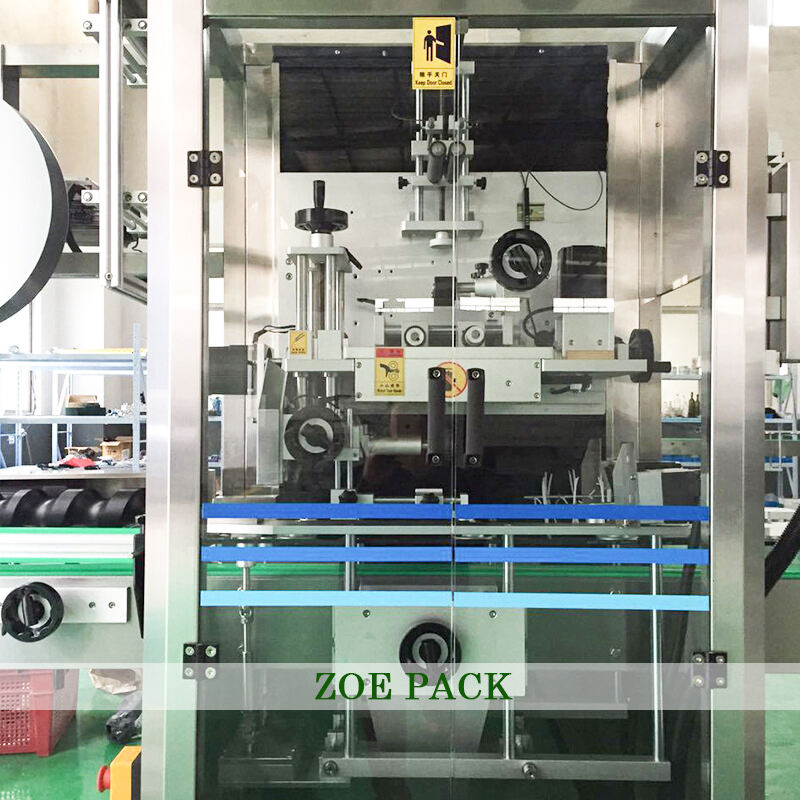

The ZOEPACK’s Automatic Horizontal Wrap Around Shrink Sleeve Label Seaming Machine is manufactured with high-quality materials that ensure durability and stability during operation. It boasts a design. This is compact features that are user-friendly which could make it quite simple to set up, run and continue maintaining.

The product is sold with sophisticated seaming that is automated that ensures perfect and flawless wrapping of shrink sleeves throughout the containers. It could manage just as many as 250 bottles every single full minute, making it perfect for high-volume manufacturing operations.

The seaming machine could be loaded with a control. This is digital that allows one to adjust the rate and heat settings with simplicity, ensuring maximized performance and consistency across all your labeling applications. Additionally, it has sensors that are innovative detect label placement, heat, and stress to ensure precision and precision in operations.

Please feel free to let us know if you need any help,we will provide a professional guidance for youl

CONTACT US