Applications

| Number of sealing head |

1 |

| Number of seaming rollers |

4(2 frst operation,2 second operation) |

| Sealing speed |

35~50 cans/ min(adjustable) |

| Sealing height |

25-220mm |

| Sealing can diameter |

35-130mm |

| Working temperature |

0-45℃ |

| working humidity |

35~85% |

| Total power |

2.1KW |

| Weight |

330KG |

| Dimensions |

L1850* W 840*H1650mm |

Features

The Advanced Carton - Forming Machine: Transforming Packaging Preparation

In the intricate web of packaging operations, the initial step of carton formation is of utmost importance. A revolutionary carton - forming machine has entered the scene, equipped with features that are redefining the efficiency and precision of this fundamental process.

Automatic Carton - Blank Feeding System: Streamlining the Start

This carton - forming machine is outfitted with an automatic carton - blank feeding system. In traditional setups, workers often had to manually load each carton blank into the machine, a time - consuming and error - prone task. With the new automatic system, carton blanks are fed continuously and precisely. Sensors detect the correct position of each blank, ensuring that it is placed accurately for the forming process. This not only speeds up the operation but also reduces the risk of misaligned cartons. For large - scale packaging facilities that handle thousands of cartons daily, this automatic feeding system can significantly increase productivity, as it eliminates the bottleneck caused by manual blank loading.

Adjustable Forming Mechanism: Versatility at its Best

The forming mechanism of this machine is highly adjustable. It can accommodate different sizes and styles of cartons, from small, delicate boxes for jewelry to large, sturdy cartons for bulky items. Operators can easily input the desired dimensions and shape parameters into the machine's control panel. The machine then adjusts its forming parts, such as folding plates and creasing tools, accordingly. This adaptability is a boon for companies that deal with a wide range of products. They no longer need to invest in multiple machines for different carton sizes; a single, versatile carton - forming machine can handle all their requirements. This flexibility also allows for quick changes in packaging design, enabling businesses to respond rapidly to market trends or new product launches.

Precise Creasing and Folding: Ensuring Structural Integrity

Precision is key when it comes to carton forming, and this machine delivers in spades. The creasing and folding operations are carried out with extreme accuracy. Specialized creasing blades create clean, sharp creases that allow the carton to fold neatly. The folding mechanism then follows the creases precisely, ensuring that the carton sides meet perfectly. This level of precision is crucial for maintaining the structural integrity of the carton. A well - formed carton can better withstand the rigors of transportation and storage. In the food industry, for example, where cartons need to protect perishable goods, a strong and properly formed carton is essential to prevent damage and spoilage.

High - Speed Operation: Meeting Demanding Production Schedules

With a high - speed operation capability, this carton - forming machine can churn out a large number of cartons in a short time. It can achieve speeds of up to [X] cartons per minute, depending on the complexity of the carton design. This makes it an ideal choice for high - volume production environments. In a busy e - commerce fulfillment center, where countless products need to be packaged daily, the fast - paced carton - forming machine can keep up with the demand. The high - speed operation also helps to reduce the overall production time, getting products to the market more quickly.

Integrated Quality Control System: Maintaining Consistency

An integrated quality control system is built into the carton - forming machine. Sensors continuously monitor the forming process, checking for any irregularities such as misfolds, incomplete creases, or incorrect sizing. If a problem is detected, the machine can either automatically correct the issue (if possible) or stop the production line and alert the operator. This real - time quality control ensures that only high - quality cartons are produced. It reduces the number of defective cartons, which in turn saves resources and minimizes waste. For companies that value product quality and brand reputation, this integrated quality control system is an invaluable feature.

Energy - Saving Design: Environmentally Conscious Packaging

In an era of growing environmental awareness, the carton - forming machine incorporates an energy - saving design. The machine's motors and other components are optimized to consume less power without sacrificing performance. For instance, the machine uses energy - efficient servo motors that adjust their power consumption based on the workload. When the machine is operating at a lower speed or during periods of inactivity, the power consumption is reduced. This not only helps companies save on their energy bills but also contributes to a more sustainable packaging process.

User - Friendly Interface: Easing Operator Interaction

The machine features a user - friendly interface that makes it easy for operators to control and monitor the carton - forming process. The control panel is equipped with a touch - screen display that provides clear instructions and real - time status updates. Operators can easily navigate through the various settings, adjust parameters, and start or stop the machine. Even those with limited technical knowledge can quickly get up to speed with the machine's operation. This user - friendliness reduces the need for extensive operator training, making it more accessible for small and medium - sized enterprises.

In conclusion, the advanced carton - forming machine, with its automatic feeding, adjustable forming mechanism, precise creasing and folding, high - speed operation, integrated quality control, energy - saving design, and user - friendly interface, is a game - changer in the packaging industry. It offers a comprehensive solution that addresses the key challenges of efficiency, versatility, quality, and sustainability in carton formation. As the packaging industry continues to evolve, machines like this will play a vital role in enabling businesses to stay competitive and meet the ever - changing demands of the market.

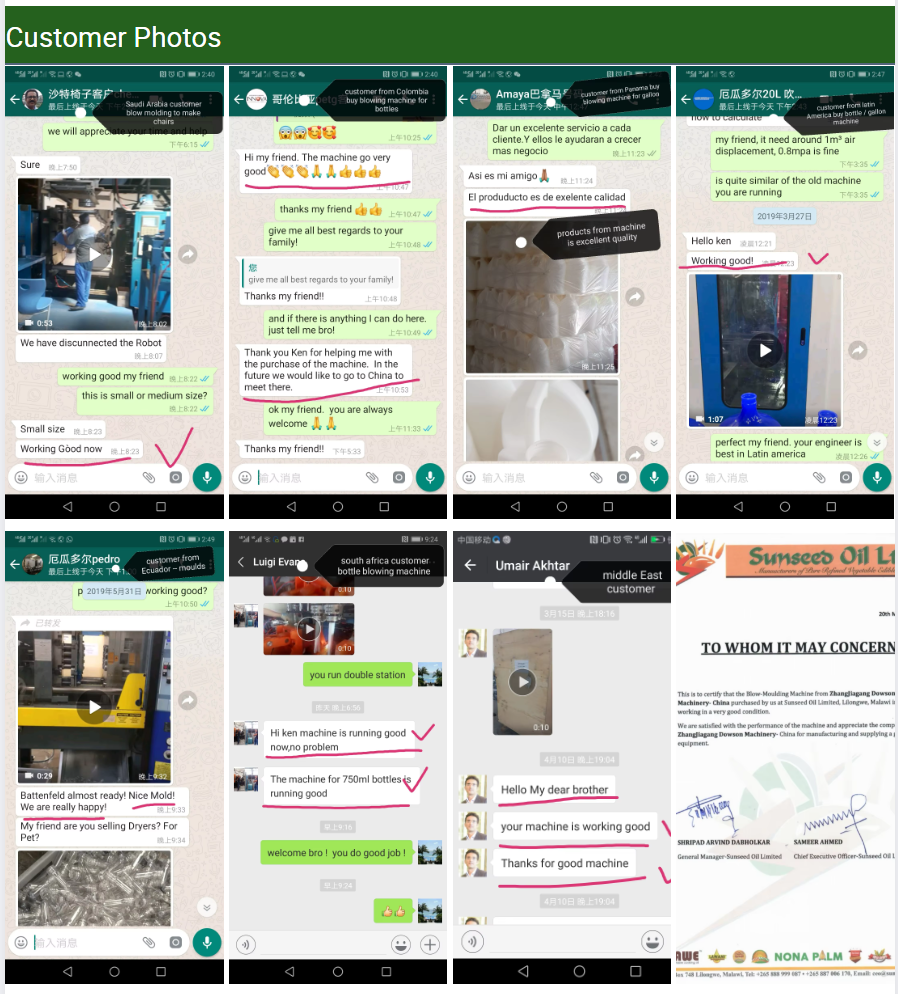

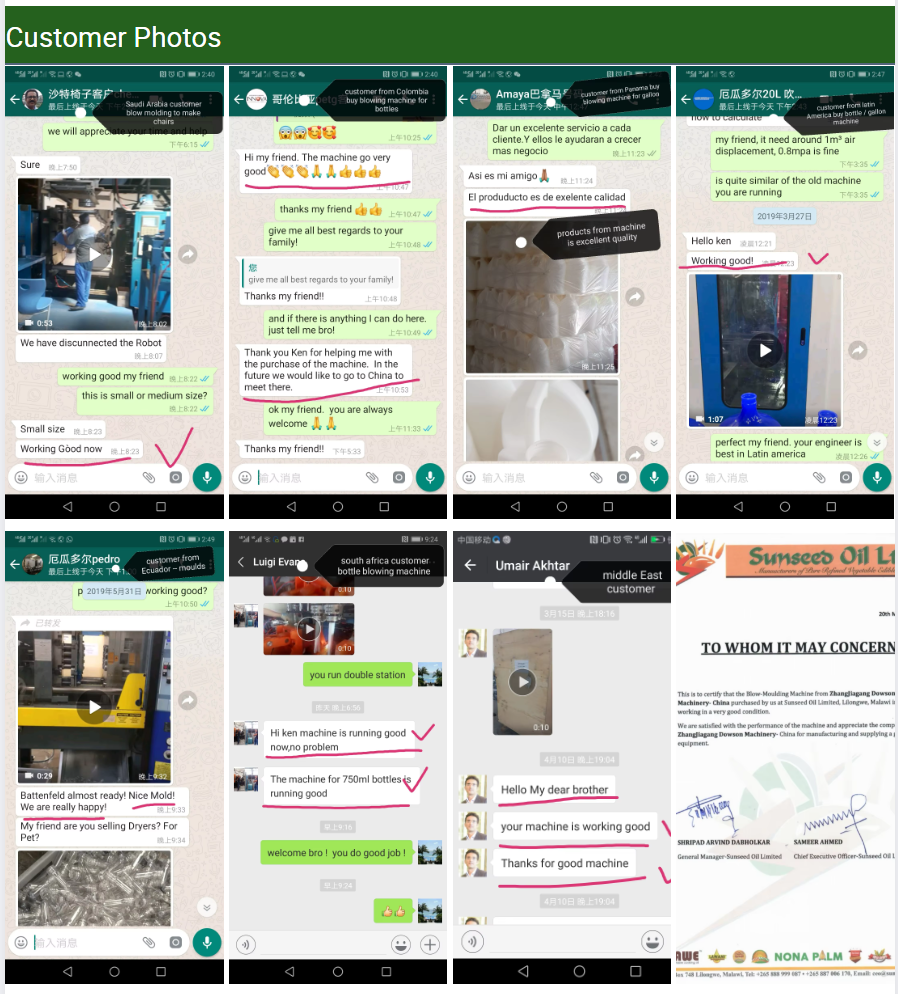

Company Profile

Zoe pack

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery,iniection molding machine, blow molding machine, PET blow molding machine, iniection blow moldinamachine, during the past 18 years, we always force our energy into new areas of plastic machinery,plastic packaging machinery, to update the technology, to leamn advanced experience,to confirm newtheory and new design, we are forming a unique competitive advantage of our owns.The machines fromour company carry good quality and effective after-sales service, upon the market,customers from more than 45 countries, we provide complete solution for your plastic industry businessas well as all sorts of technical support & after-sale services!

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you canfly to Shanghai Pudong International Airport, We can pick you up in the Airport. (or HongqiaoInternational Airport.)We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommendour machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q: How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRSonline support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. For stock machine, fast shipment. (The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design themachines according to customers products to meet customer' needs.

Q:How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation andcommission the machine, also train the customer's employees.

Q: What's ZOE PACK's advantage?

ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and moldinstallation, debugging, also we can source the auxiliary equipment for customers. We can ship the fullset of machines after testing in our factory. It will save a lot of cost and time.

ZOE PACK will be your reliable friend in china, and we will always do our best to give you max support!