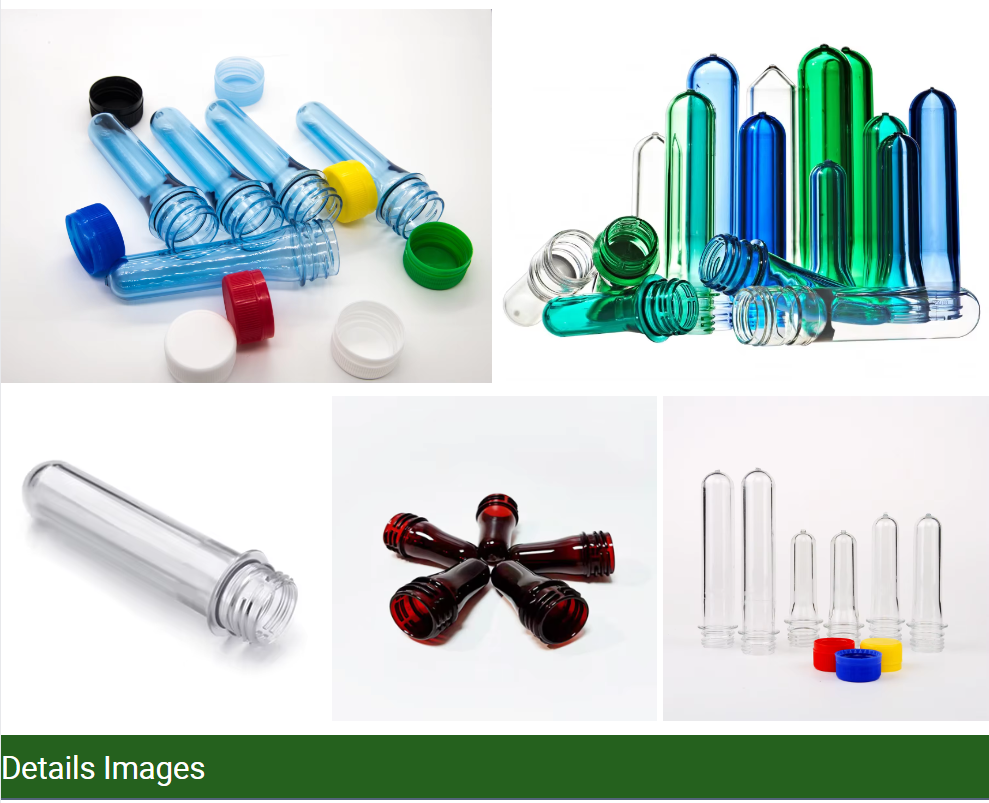

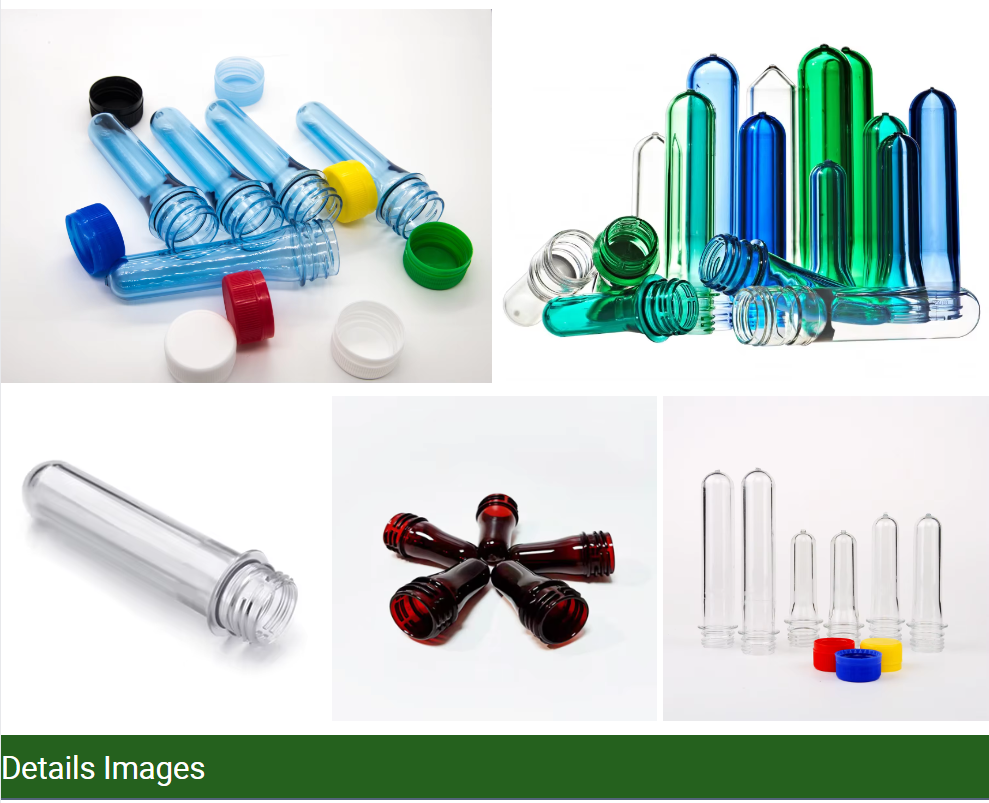

PET Preform Injection Blow Molding Machine

The PET preform injection - blow molding machine is an equipment of crucial significance in the field of plastic processing. It is mainly used to produce PET (polyethylene terephthalate) preform products, which are the key intermediate products for manufacturing PET bottles.

In terms of principle, first comes the injection molding stage. During this process, PET pellets are heated to their molten state, and then the molten PET material is injected into a specially - made preform mold through the rotation of the screw. The design of this mold is very precise, which determines the shape and size of the preform product, such as the neck thread of the bottle blank and the overall wall thickness distribution. The injection process requires precise control of parameters such as temperature, pressure, and injection speed.

Then comes the blow - molding stage. After the preform product has been injection - molded and cooled to a certain extent, it is transferred to the blow - molding mold. At this time, high - pressure air is blown into the interior of the preform product, causing the preform product to expand and conform to the shape of the blow - molding mold under the restriction of the mold, and finally forming the shape of the PET bottle we need. This two - step process ensures the high quality and precise shape control of PET bottles.

The PET preform injection - blow molding machine has a wide range of applications in numerous industries such as beverage, food, and cosmetics. For example, in the beverage industry, it can efficiently produce PET bottles for holding various beverages, from mineral water bottles to carbonated beverage bottles. Due to the good transparency, barrier properties, and recyclability of PET materials, the bottle products produced by the PET preform injection - blow molding machine are highly favored in the market. At the same time, this machine has high production efficiency and can meet the needs of large - scale production. Moreover, with the continuous development of technology, it can also continuously increase the production speed and reduce the production cost while ensuring product quality.