The maintenance and upkeep of the PET preform injection - blow molding machine are essential for ensuring the normal operation of the machine, extending its service life, and guaranteeing product quality.

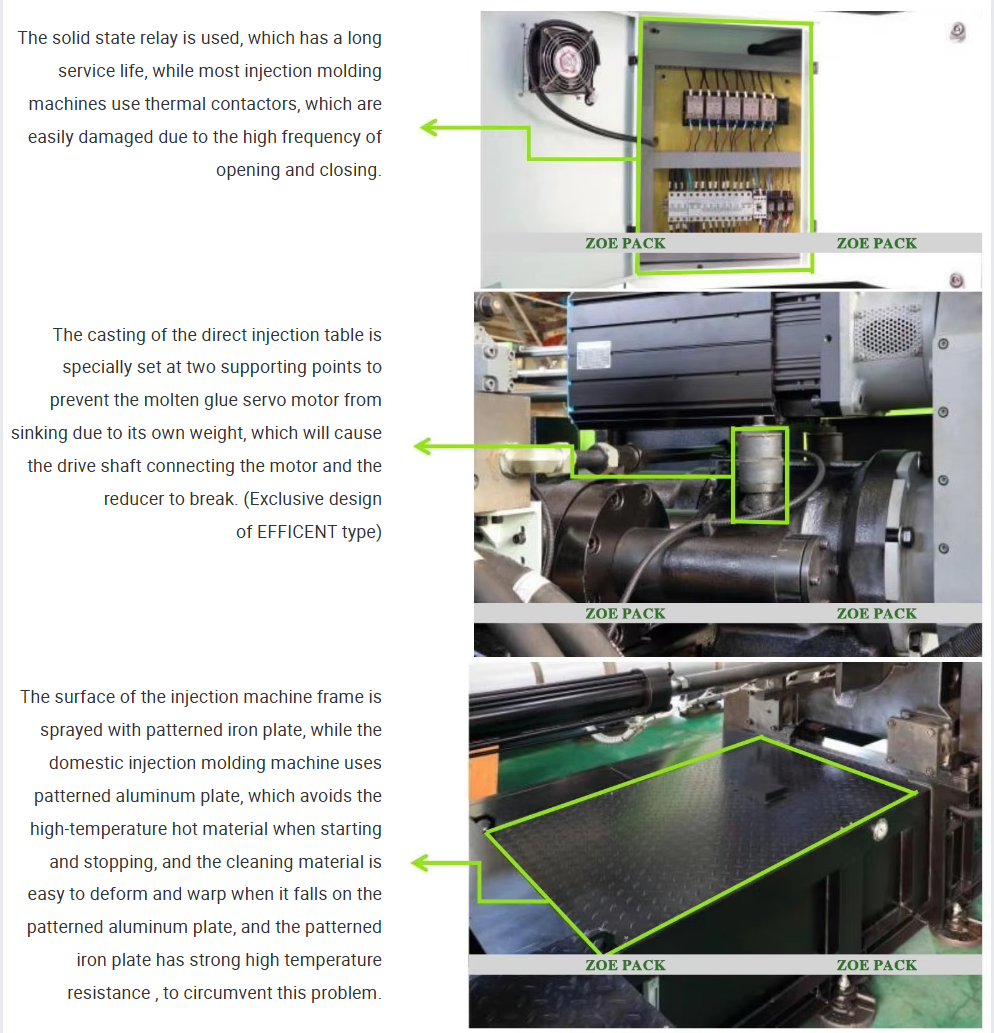

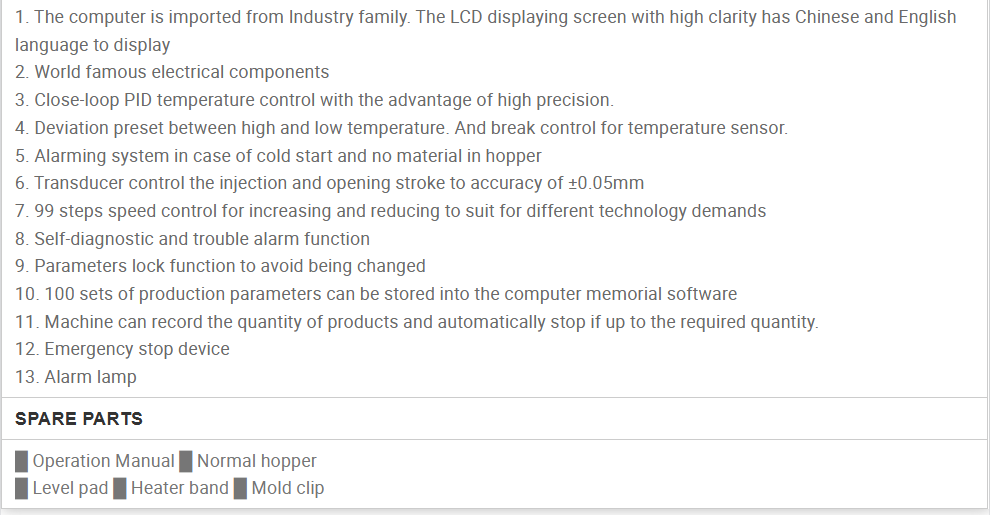

First, for the maintenance of the heating system. The heating barrel is a key component for heating PET materials. Due to the long - term high - temperature working environment, the heating elements inside may age or be damaged. Regular inspection of indicators such as the resistance value and insulation performance of the heating elements is necessary. If the performance of the heating elements is found to decline, they should be replaced in a timely manner. At the same time, the insulation layer outside the heating barrel also needs to be inspected regularly to ensure its good insulation effect and avoid excessive heat dissipation. In addition, the accuracy of temperature sensors is also crucial for the normal operation of the heating system. Temperature sensors should be calibrated regularly to ensure the accuracy of temperature control.

The screw is one of the core components of the injection - molding unit. It will be worn by PET materials during long - term use. Therefore, it is necessary to regularly check the wear condition of the screw, especially the screw flights and the head. If the screw is severely worn, it will affect the material conveyance and plasticizing effect, resulting in a decline in product quality. When checking the screw wear, professional measuring tools such as calipers can be used. For a worn screw, it can be repaired or directly replaced. At the same time, to reduce the wear of the screw, it is necessary to ensure the cleanliness of PET materials and avoid the mixing of impurities.

The maintenance of the preform mold and the blow - molding mold cannot be ignored. During the use of the molds, dirt and plastic residues will accumulate on the surface of the mold cavity, which will not only affect the surface quality of the product but also may cause mold corrosion. Regular cleaning of the molds is necessary. Special mold - cleaning agents can be used when cleaning. After cleaning, the surface of the mold cavity should be polished to restore its surface smoothness. In addition, the cooling systems of the molds also need to be inspected regularly to ensure that the cooling channels are unobstructed and the cooling effect is good. If the cooling system fails, it will cause the mold temperature to be too high or too low, affecting the forming quality of the product.

If it is a hydraulically - driven machine, the hydraulic system is an important part for providing power. Regular inspection of the oil quality and oil level of the hydraulic oil is required. If the hydraulic oil is contaminated or the oil level is too low, it will affect the normal operation of the hydraulic system and may even cause damage to hydraulic components. Regular replacement of the hydraulic oil and filtration and cleaning of the hydraulic system to remove impurities and moisture are necessary. At the same time, the working state of hydraulic components such as hydraulic pumps and hydraulic valves should be checked, such as whether there is leakage or excessive noise. If any problems are found, they should be repaired or replaced in a timely manner.

For the electrical system, it is necessary to regularly check whether the wires and cables are damaged or aged, and whether the electrical components in the electrical control cabinet are working normally. Ensure good grounding to avoid electrical accidents caused by electrical faults. In addition, the software of the control system should also be regularly backed up and updated to ensure the stability and advanced functionality of the system. Operators should strictly follow the operating procedures during daily operations to avoid damage to the machine due to misoperation. Through the above comprehensive maintenance and upkeep measures, the PET preform injection - blow molding machine can be maintained in a good operating state, improving production efficiency and product quality.