Applications

| Number of sealing head |

1 |

| Number of seaming rollers |

4(2 frst operation,2 second operation) |

| Sealing speed |

35~50 cans/ min(adjustable) |

| Sealing height |

25-220mm |

| Sealing can diameter |

35-130mm |

| Working temperature |

0-45℃ |

| working humidity |

35~85% |

| Total power |

2.1KW |

| Weight |

330KG |

| Dimensions |

L1850* W 840*H1650mm |

Features

The Superiority of Automatic Jar Sealing Machine

In the modern packaging industry, the Automatic Jar Sealing Machine has emerged as a revolutionary device, bringing about a series of remarkable improvements in the can - sealing process. This article will delve into the key features that make this machine stand out in the market, highlighting its technological advancements and practical advantages.

Whole Machine Servo Control: A Leap in Stability and Intelligence

The adoption of whole machine servo control in the Automatic Jar Sealing Machine is a game - changer. Servo control systems are known for their high precision and reliability. By using servo motors to drive various components of the machine, it ensures smooth and stable operation. This stability is crucial as it directly impacts the quality of the can - sealing process. For example, during the seaming operation, the servo - controlled seaming rollers can apply a consistent and accurate amount of force. This results in a more uniform seal around the can lid, reducing the chances of leaks or improper seals.

Moreover, the intelligence of the servo - controlled system allows for better adaptability. It can be programmed to adjust the sealing parameters according to different can sizes, lid types, and product requirements. This means that manufacturers can quickly switch between different production runs without the need for extensive manual re - calibration. For instance, if a food - processing company needs to seal both small - sized jam jars and large - sized pickle cans, the Automatic Jar Sealing Machine can be easily reprogrammed to handle these different tasks with optimal efficiency.

Turntable Operation Based on Can Detection

The feature that the turntable only runs when there is a can is a prime example of the machine's intelligent design. This not only saves energy but also enhances the overall safety and efficiency of the operation. Equipped with advanced sensors, the machine can detect the presence of a can on the turntable. When a can is placed in the correct position, the turntable starts rotating, moving the can to the sealing station. If no can is detected, the turntable remains stationary.

This can - detection mechanism is particularly useful in preventing unnecessary wear and tear on the machine. In traditional can - sealing machines, the turntable often runs continuously, even when there are no cans to be processed. This not only wastes energy but also increases the frequency of maintenance due to the constant operation of components. With the Automatic Jar Sealing Machine's can - detection feature, the machine's lifespan is extended, and operating costs are reduced. Additionally, it minimizes the risk of accidents, as there is no chance of the turntable running without a can, which could potentially cause damage to the machine or injury to operators.

One - Button Reset: Simplifying Operations

The one - button reset function is a user - friendly feature that greatly simplifies the operation of the Automatic Jar Sealing Machine. In any industrial setting, machinery malfunctions or unexpected stops can occur. When this happens, the one - button reset comes to the rescue. With just a single press of a button, the machine can quickly return to its initial setup state.

This feature is extremely valuable for several reasons. First, it saves time. In a production line where every second counts, a quick reset can prevent long - term disruptions. For example, if a minor glitch causes the machine to stop during a high - volume production run, the operator can simply press the reset button instead of spending valuable minutes troubleshooting and manually re - setting the machine. Second, it reduces the need for highly skilled technicians to be present at all times. Even an operator with basic training can perform a one - button reset, ensuring that the production process can resume smoothly without waiting for an expert to arrive.

Simultaneous Operation of Four Seaming Rollers: High Sealing Performance

The Automatic Jar Sealing Machine's ability to complete the seaming process with a total of 4 seaming rollers simultaneously is a testament to its high - performance design. When these four rollers work in unison, they apply a balanced and comprehensive force around the can lid. This results in a significantly higher - quality seal compared to machines with fewer rollers.

The high - sealing performance is especially crucial for products that require a tight seal to maintain their freshness, integrity, or safety. For example, in the pharmaceutical industry, where products need to be protected from contamination, the strong and reliable seal provided by the four - roller system ensures that the medicine remains uncontaminated until it reaches the consumer. In the food and beverage industry, a high - quality seal is essential to prevent spoilage and extend the shelf life of products. The simultaneous operation of the four seaming rollers also speeds up the sealing process, allowing for higher production volumes within a given time frame.

Non - Rotating Can Body during Sealing: Safety and Product Suitability

The fact that the can body does not rotate during the sealing process is a unique and highly beneficial feature of the Automatic Jar Sealing Machine. This design is particularly suitable for fragile and liquid products. For fragile products, such as glass jars containing delicate items like artisanal chocolates or handmade candles, the non - rotating can body eliminates the risk of breakage due to excessive movement or vibration during sealing.

In the case of liquid products, such as bottled sauces or beverages, a non - rotating can body ensures that the liquid remains stable inside the can. There is no sloshing or splashing that could potentially lead to spills or inaccurate filling levels. This not only improves the safety of the sealing process but also enhances the quality of the final product. Additionally, the non - rotating can body design simplifies the overall construction of the machine, as there is no need for complex mechanisms to control the rotation of the can.

High Sealing Speed: Meeting Production Demands

With a sealing speed of up to 50 cans per minute, the Automatic Jar Sealing Machine is well - equipped to meet the high - volume production demands of modern industries. This high speed is a result of its advanced design and efficient components. The servo - controlled systems, the coordinated operation of the seaming rollers, and the intelligent can - detection mechanism all contribute to this rapid sealing process.

For large - scale food - processing plants, beverage manufacturers, or pharmaceutical companies, the ability to seal a large number of cans in a short period is essential for maintaining productivity and competitiveness. The high sealing speed also allows for faster turnaround times, enabling companies to respond more quickly to market demands. For example, during peak seasons, such as the holiday season for food products, the Automatic Jar Sealing Machine can help manufacturers increase their production capacity to meet the increased consumer demand.

Transparent Blue Acrylic Cover: Combining Aesthetics and Safety

The transparent blue acrylic cover of the Automatic Jar Sealing Machine serves both aesthetic and safety purposes. Visually, the blue - tinted cover gives the machine a modern and attractive appearance. It stands out in a production facility, adding a touch of professionalism and style.

From a safety perspective, the transparent cover allows operators to monitor the sealing process without having to open the machine. They can observe the movement of the cans, the operation of the seaming rollers, and any potential issues that may arise. At the same time, the cover acts as a physical barrier, protecting operators from moving parts and hot components. This multiple - protection feature ensures a safe working environment while maintaining the visual appeal of the machine.

In conclusion, the Automatic Jar Sealing Machine, with its advanced features such as whole machine servo control, intelligent turntable operation, one - button reset, high - performance seaming with four rollers, non - rotating can body, high sealing speed, and the transparent blue acrylic cover, represents the pinnacle of modern can - sealing technology. It offers a combination of stability, efficiency, safety, and aesthetics that is unrivaled in the market, making it an ideal choice for a wide range of industries.

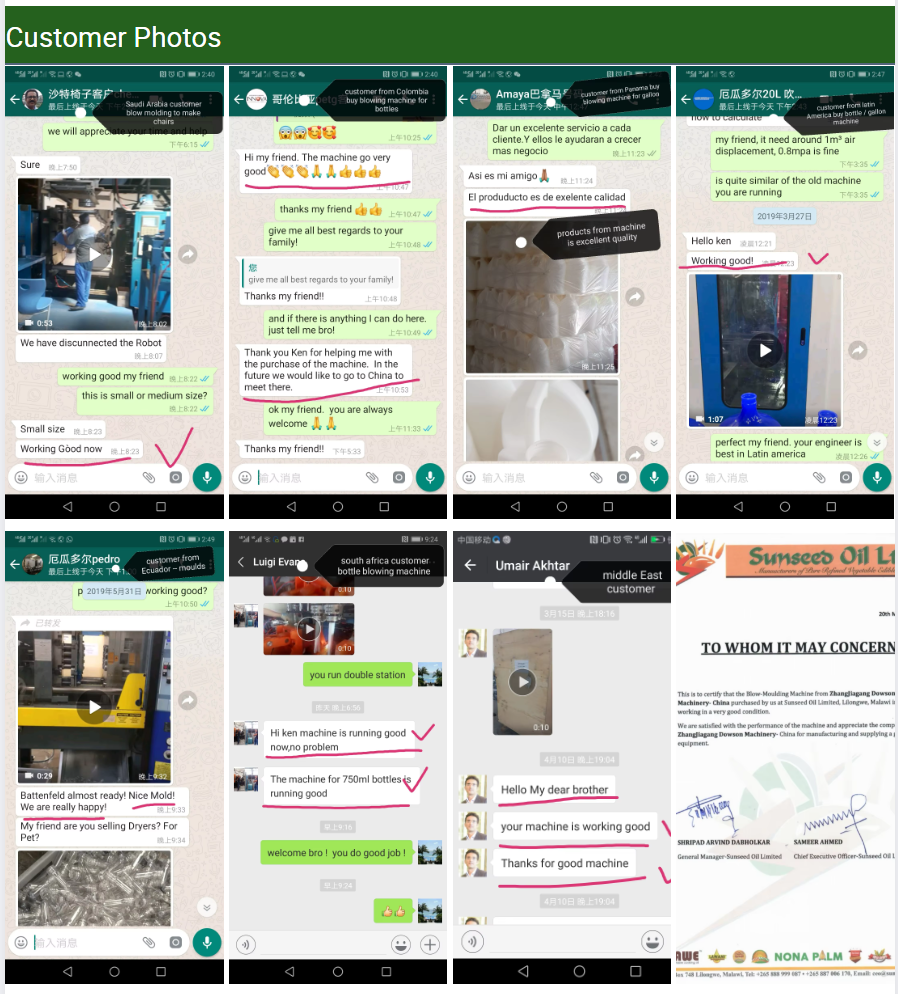

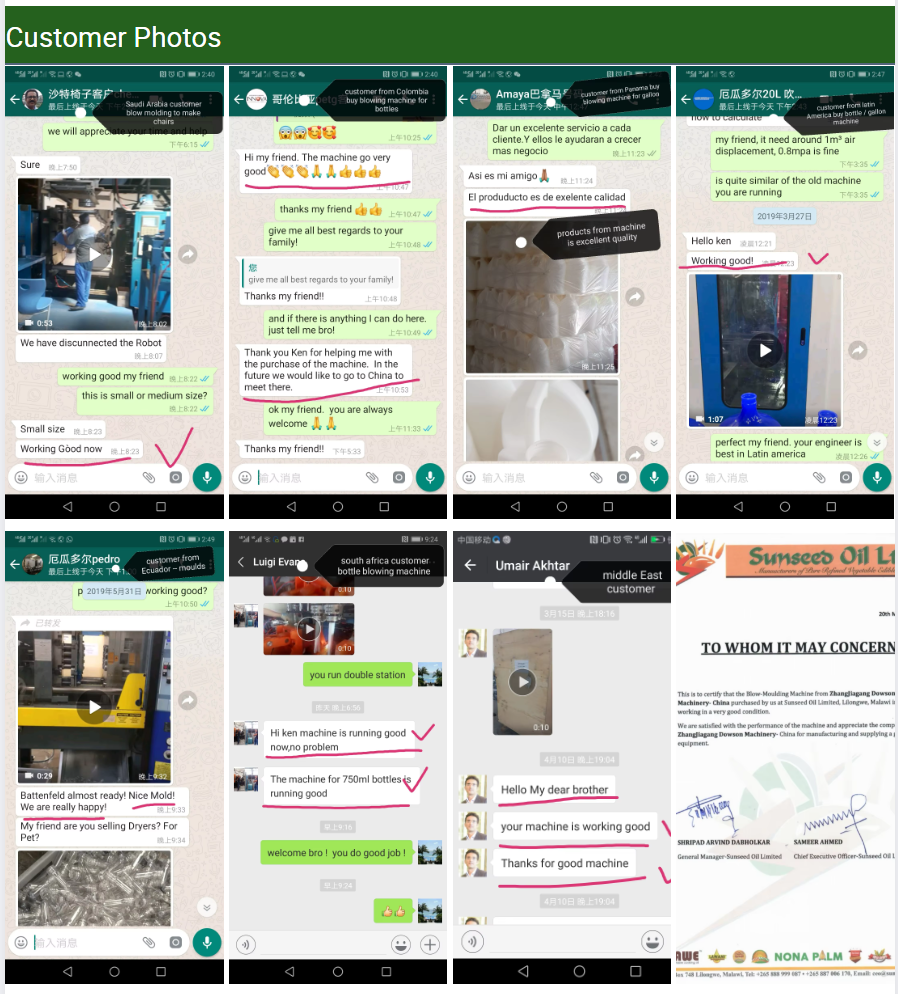

Company Profile

ZOE PACK

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery,injection molding machine, blow molding machine, PET blow molding machine, injection blow moldingmachine, during the past 18 years, we always force our energy into new areas of plastic machinery,plastic packaging machinery, to update the technology, to learn advanced experience,to confirm newtheory and new desian, we are forming a unigue competitive advantage of our owns,The machines fromour company carry good quality and effective after-sales service, upon the market,customers from more than 45 countries, we provide complete solution for your plastic industry business,as well as all sorts of technical support & after-sale services!

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!

FAQ

Q: Can we visit your factory?

Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you canfly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or HongqiaoInternational Airport. )We also provide visit online by video.

Q: How can we get the exact price of plastic machine?

Contact us with the products size, shape, annual quantity and photo if possible. We can recommendour machine models with quotation.

Q: Do you provide any spare parts with machine?

Yes, we offer all necessary spare parts before shipment.(contact us for packing list )

Q :How about your after-sale service ?

We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist.

Q: What is the lead time?

For customized machine, it takes about 45-50 days after deposit. Forstock machine, fast shipment. (The actual production cycle will vary according to the degree of customization.)

Q: What is the warranty period for your machine ?

12 months warranty for components and technical support.

Q: Do you provide custom machines?

Most of our machines are customized. Our goal is efficiency and stable performance. We design themachines according to customers products to meet customer' needs.

Q: How can we install the machine when it arrives?

We can send experienced technicians to customer's country for guiding the installation andcommission the machine, also train the customer's employees.

Q: What's ZOE PACK's advantage?

ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and moldinstallation, debugging, also we can source the auxiliary equipment for customers. We can ship the fullset of machines after testing in our factory. It will save a lot of cost and time.

ZOE PACK will be your reliable friend in china, and we will always do our best to give you max support!