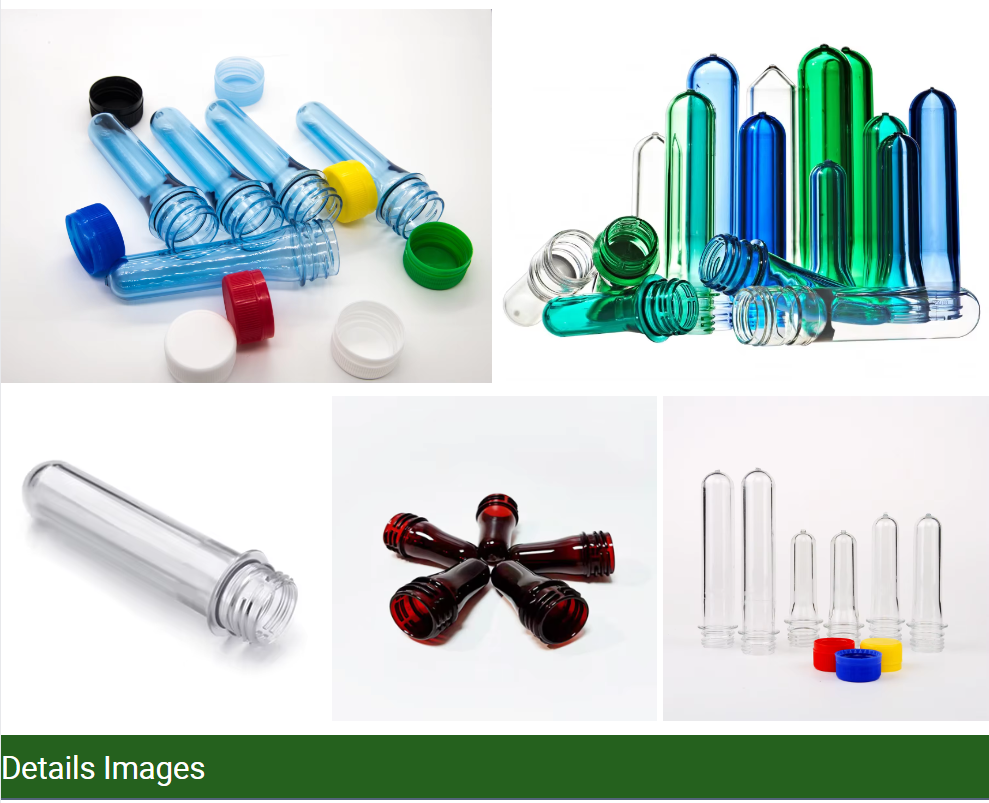

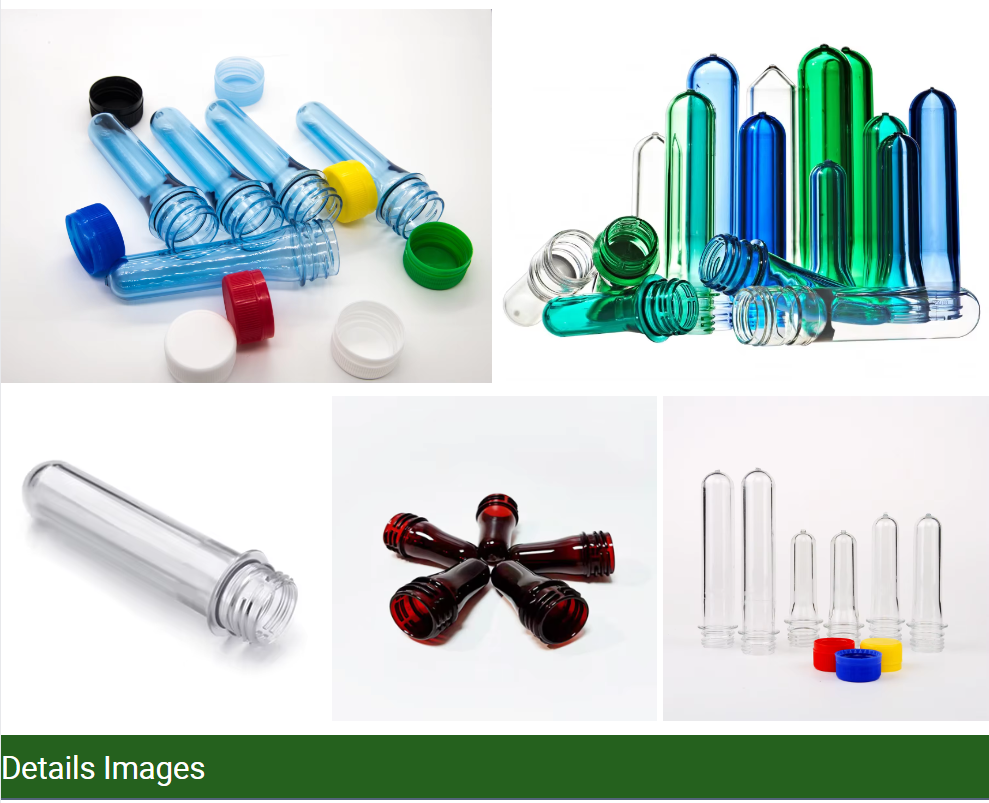

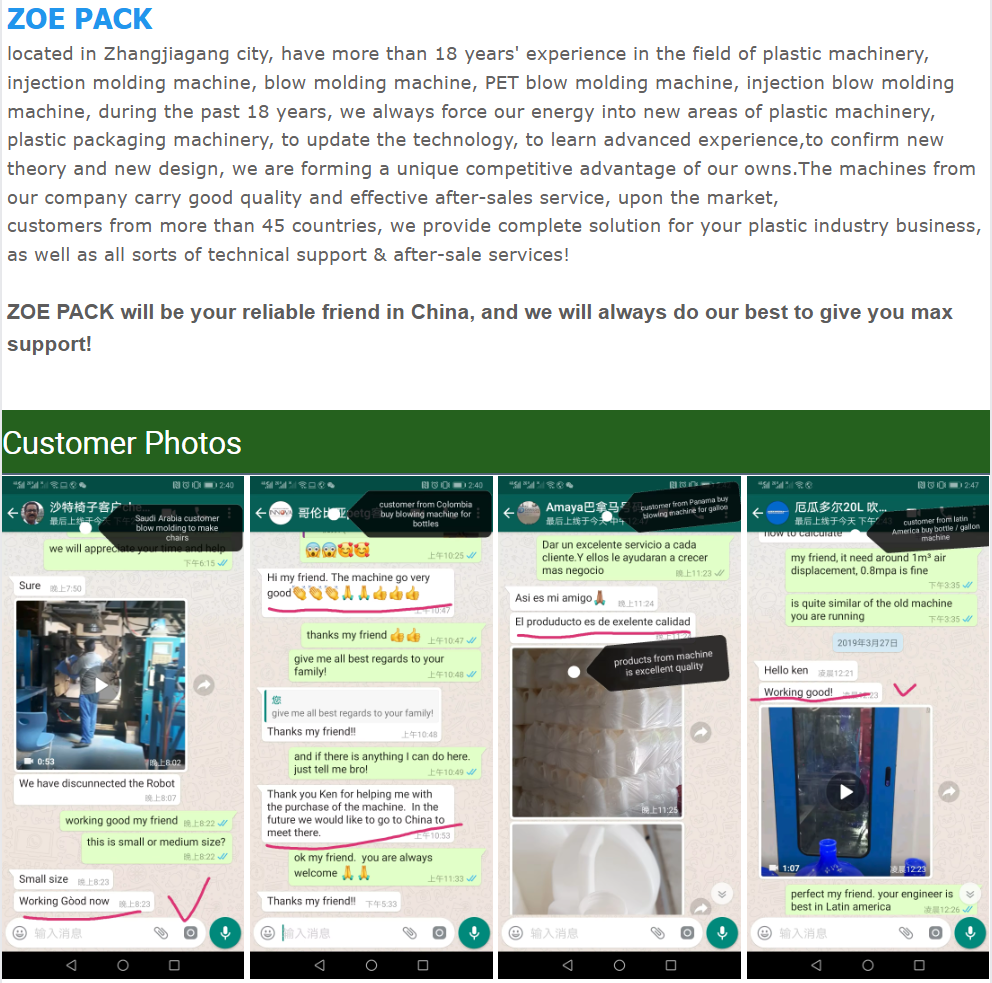

PET Prefrom Injection Molding Machine

PET preform injection - blow molding machines have a unique position in the field of plastic forming. Compared with other plastic forming processes, they have both advantages and certain limitations.

Compared with the extrusion forming process, PET preform injection - blow molding machines have higher precision in producing hollow products such as PET bottles. Extrusion forming is mainly suitable for producing continuous - shaped plastic products such as pipes and profiles. Although it may have high production efficiency, for products like PET bottles that require high precision in shape and wall thickness, extrusion forming is difficult to achieve the forming effect of PET preform injection - blow molding machines. PET preform injection - blow molding machines can produce PET bottles with uniform wall thickness, complex shapes, and high precision through precise control of the injection and blow - molding stages, such as bottles with special bottle - mouth designs or body curves.

Compared with the injection - molding process alone, PET preform injection - blow molding machines have unique advantages in producing hollow plastic products. Injection - molding is mainly used to produce solid plastic products, such as various plastic parts and injection - molded boxes. Although injection - molding can produce high - precision products, for hollow - structured PET bottles, it is difficult to directly obtain a hollow product structure if only injection - molding is used. The PET preform injection - blow molding machine combines injection and blow - molding. First, a preform product is injection - molded, and then a hollow PET bottle is formed through blow - molding. This process is more suitable for the production of hollow plastic products.

However, PET preform injection - blow molding machines also have some limitations. For example, the equipment is relatively complex, involving two different process steps of injection and blow - molding, which requires higher equipment maintenance and operation technical requirements. In contrast, some simple plastic forming processes, such as thermoforming processes, have simple equipment structures and are relatively easy to operate and maintain. The thermoforming process is suitable for producing some thin - walled, shallow - drawn plastic products, such as disposable plastic cups and food packaging boxes. Although the precision of the products produced is not as high as that of PET bottles produced by PET preform injection - blow molding machines, it has advantages in the production of products with low precision requirements, large production volumes, and cost - sensitivity.

In addition, in terms of production efficiency, for some specific plastic products, such as large - scale plastic sheets, the extrusion - forming process may have higher production efficiency. Because extrusion - forming is a continuous production process, while each PET bottle produced by a PET preform injection - blow molding machine needs to go through injection and blow - molding steps, and the production time for a single product may be relatively long. However, when producing small - batch and multi - variety PET bottles, PET preform injection - blow molding machines can improve production efficiency through technologies such as quick - mold - change to meet the diverse market demands.