PET Preform Injection Blow Molding Machine

The PET preform injection - blow molding machine consists of several important structural components, which work together to ensure the efficient operation of the machine and product quality.

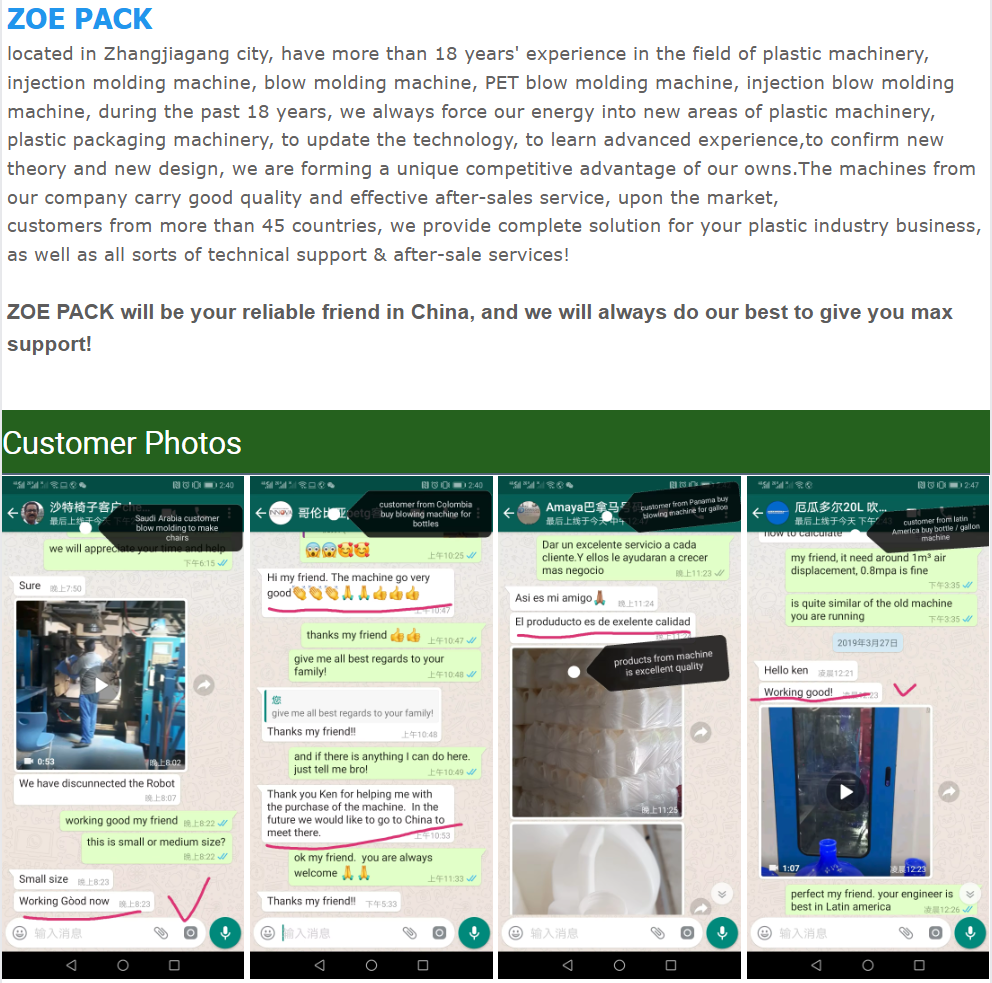

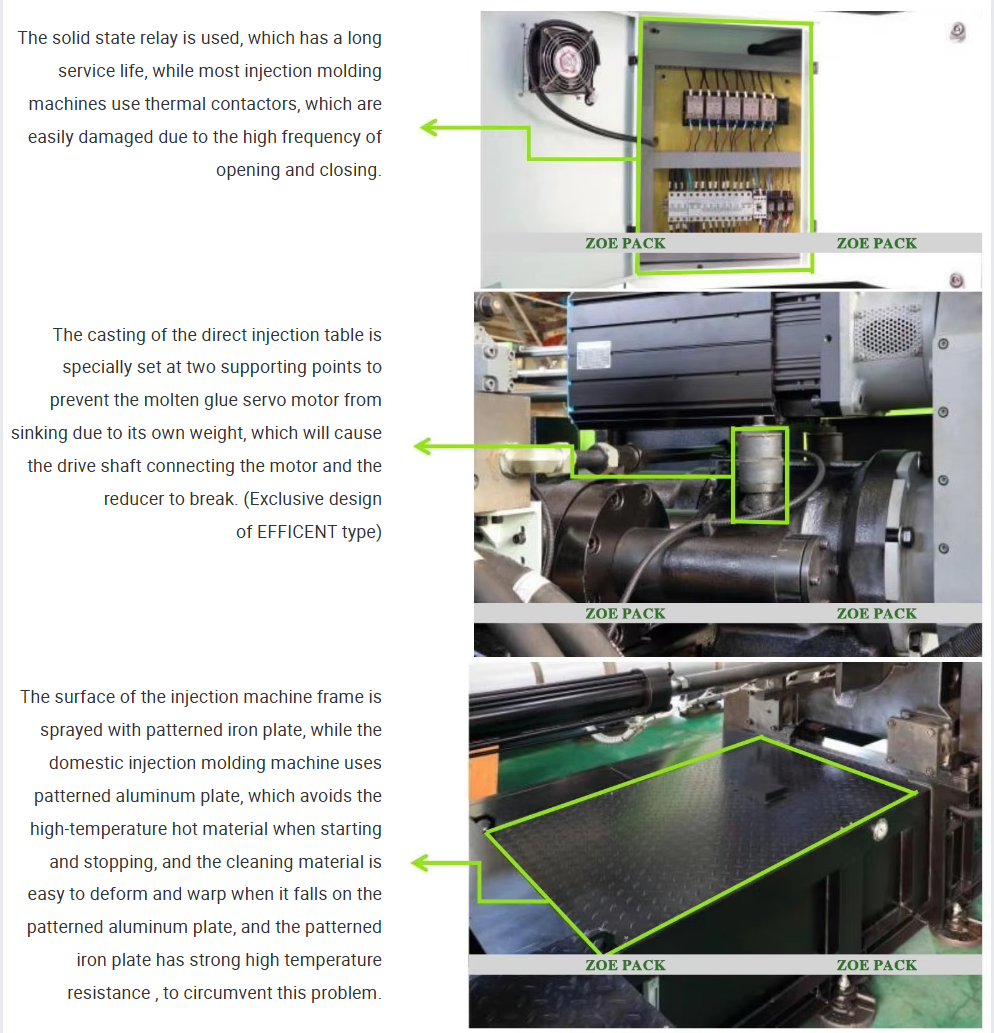

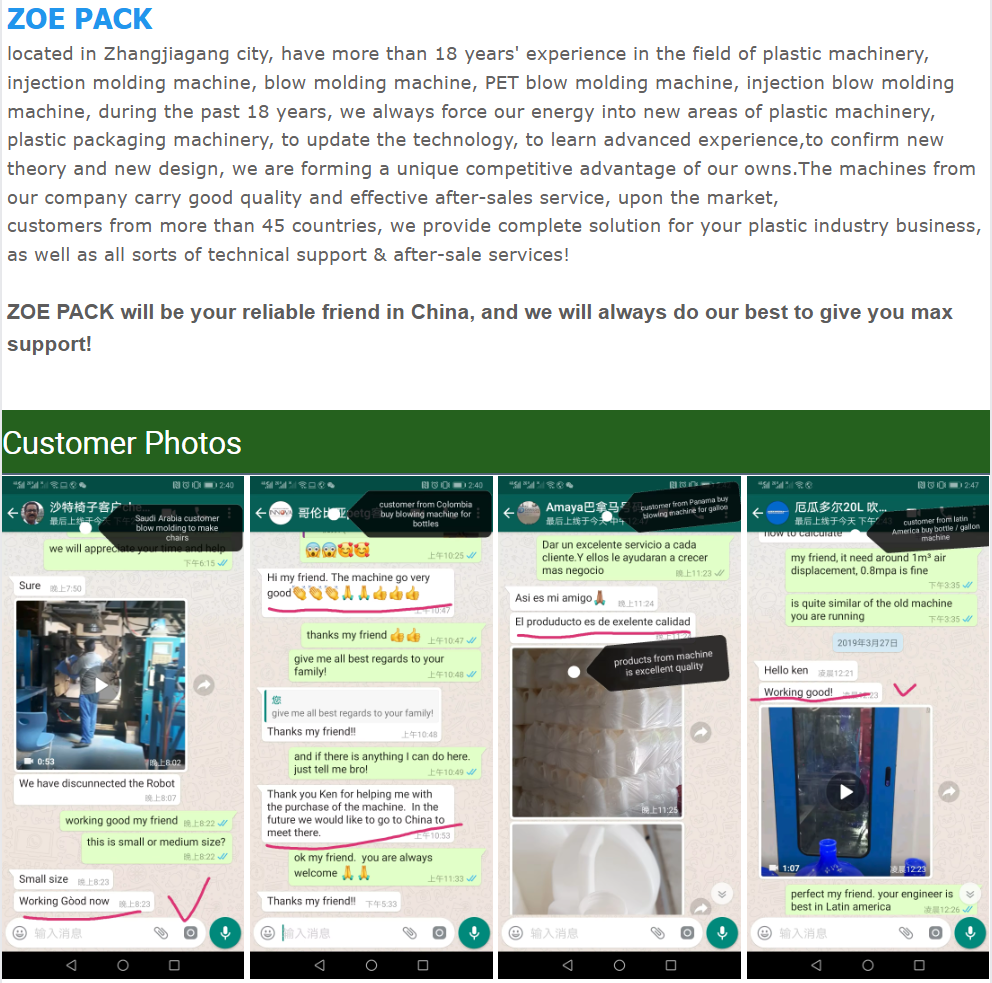

First is the injection - molding unit. The injection - molding unit includes a hopper, which is used to store PET pellet raw materials. These pellets enter the heating barrel through the hopper. The heating barrel is equipped with a precise heating system that can heat the PET pellets to an appropriate molten temperature. Inside the heating barrel, the screw plays a crucial role. The screw rotates to push the PET material forward while mixing and plasticizing it. The design of the screw varies according to different production requirements. For example, parameters such as its pitch and diameter will affect the material conveyance and plasticizing effect.

The injection - molding unit also includes a nozzle. The nozzle connects the heating barrel and the preform mold. It is responsible for injecting the molten PET material precisely into the mold cavity. The temperature control of the nozzle is also very critical to ensure the fluidity and stability of the material during the injection process.

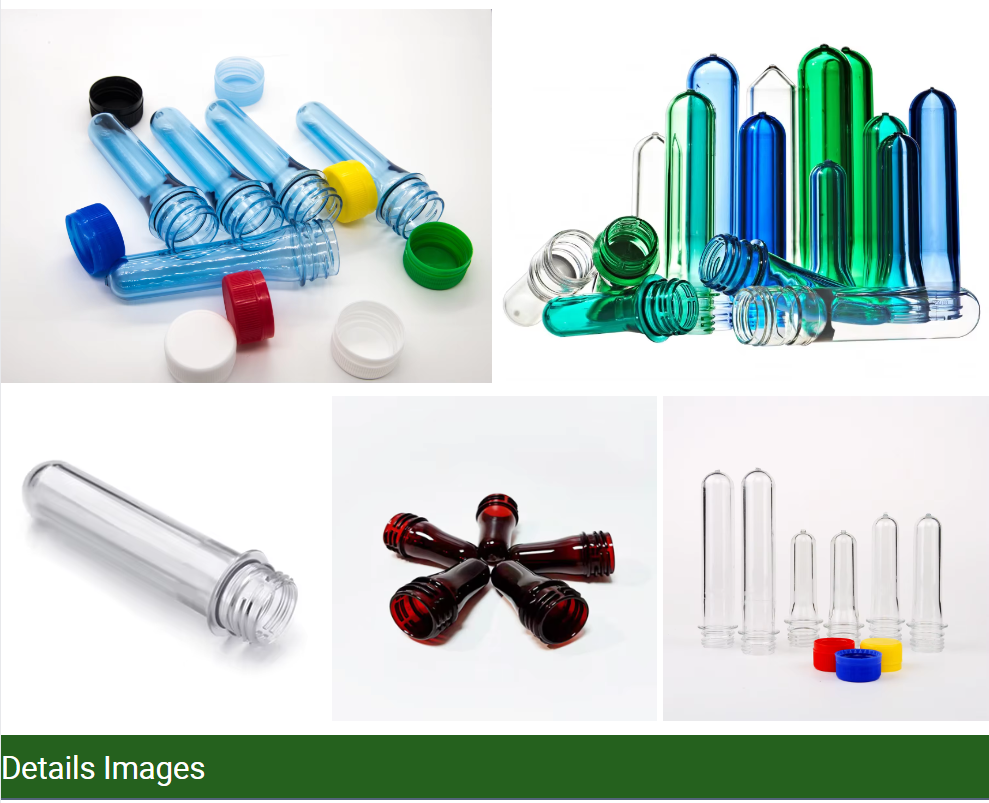

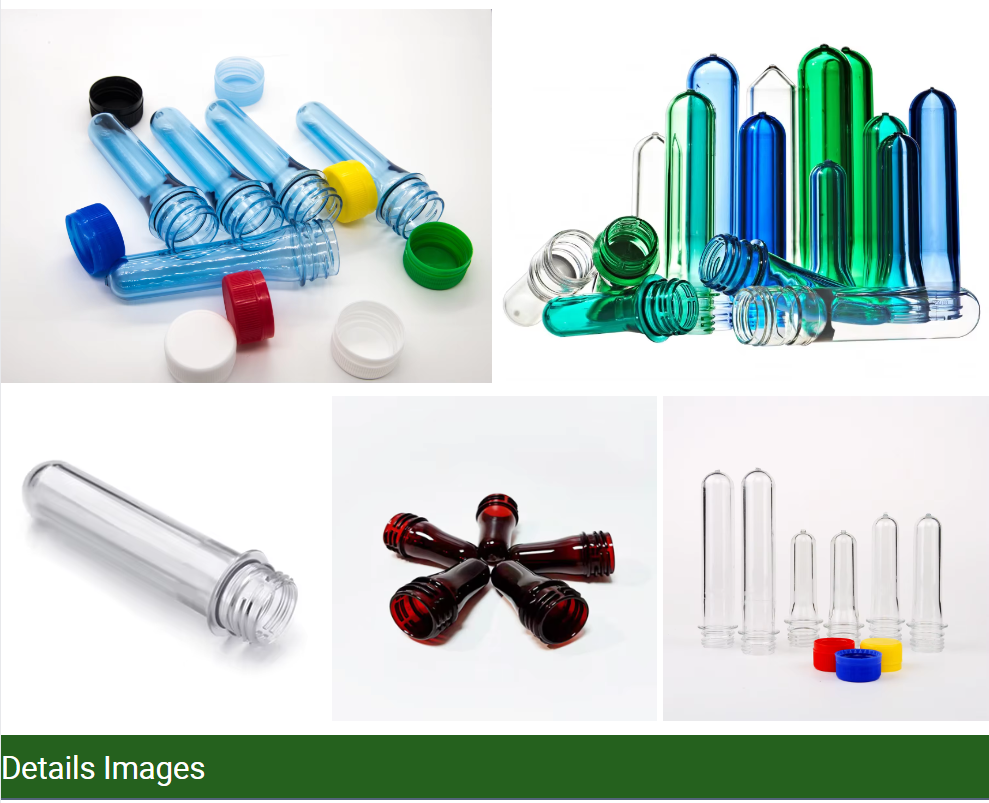

The preform mold is another core component. The material of the preform mold is usually high - quality steel to withstand the high - temperature and high - pressure working environment. The cavity structure inside the mold is complex and precise, which determines the shape, size, and surface quality of the preform product. To improve production efficiency, some advanced PET preform injection - blow molding machines are equipped with multi - cavity molds, which can produce multiple preform products in one injection process.

The blow - molding unit is also indispensable. The blow - molding unit includes the blow - molding mold and the blowing system. The shape of the blow - molding mold matches the shape of the final product, such as the shape of a bottle. The blowing system can provide a stable high - pressure air source and blow high - pressure air accurately into the interior of the preform product. During the blow - molding process, the control of pressure is very important. Excessively high or low pressure will affect the product quality, such as uneven wall thickness or bottle deformation.

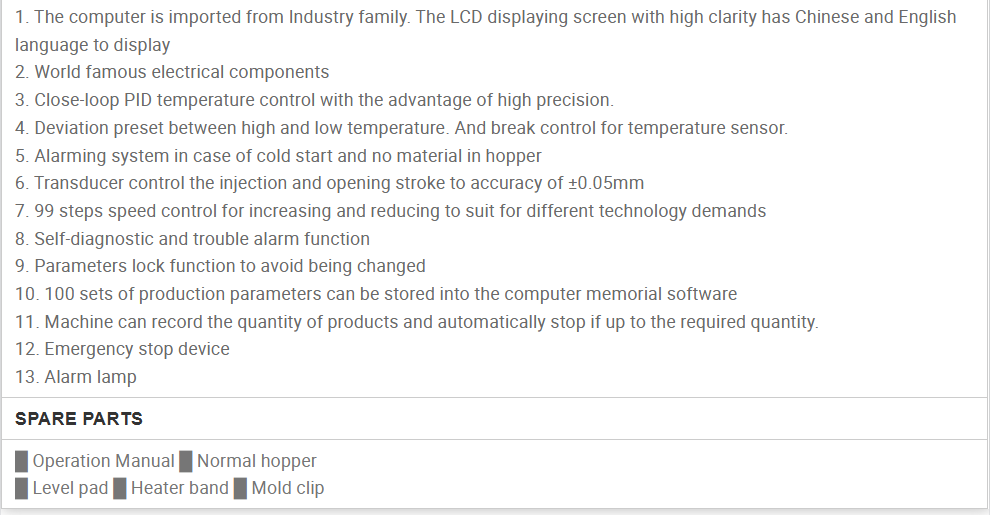

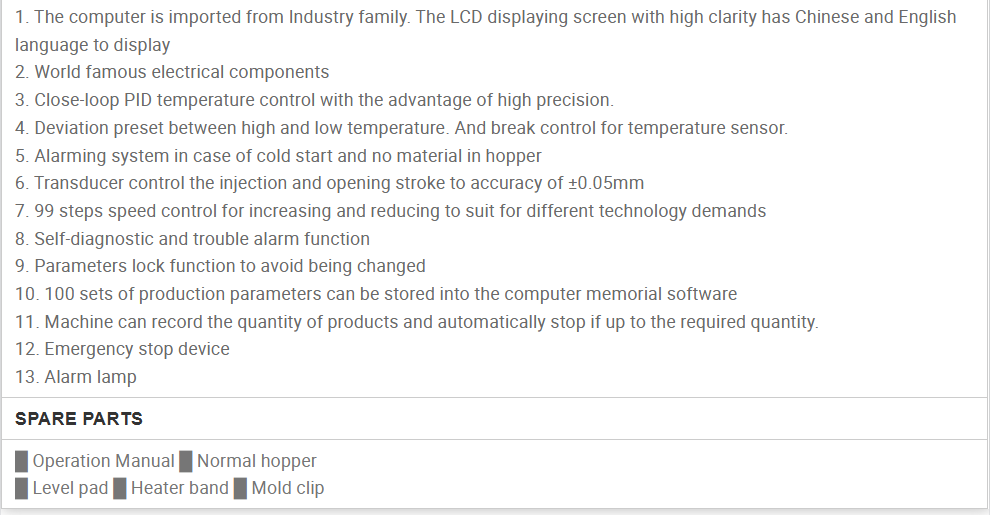

In addition, the entire PET preform injection - blow molding machine is equipped with a control system. The control system is responsible for monitoring and adjusting the operating parameters of each component, such as temperature, pressure, speed, etc. Through advanced sensors and control algorithms, operators can conveniently set and adjust parameters on the operation panel to adapt to different production requirements. At the same time, the control system also has a fault - diagnosis function, which can detect abnormal situations during the operation of the machine in a timely manner and send out alarms, facilitating maintenance personnel to carry out maintenance and repair.