PET Preform Injection Molding Machine

In the production process of the PET preform injection - blow molding machine, quality control is a crucial link to ensure product quality.

In terms of raw materials, the quality of PET materials directly affects the quality of the final product. Therefore, strict quality inspection of PET pellets is required at the feeding stage. This includes checking indicators such as the purity, molecular - weight distribution, and water content of the pellets. High - purity PET materials can ensure that the product has good transparency and physical properties; an appropriate molecular - weight distribution is helpful for the uniform plasticizing of the material during the injection - molding and blow - molding processes; and a low water content can avoid defects such as bubbles during the processing. Only PET materials that pass the inspection are allowed to enter the injection - blow - molding machine for processing.

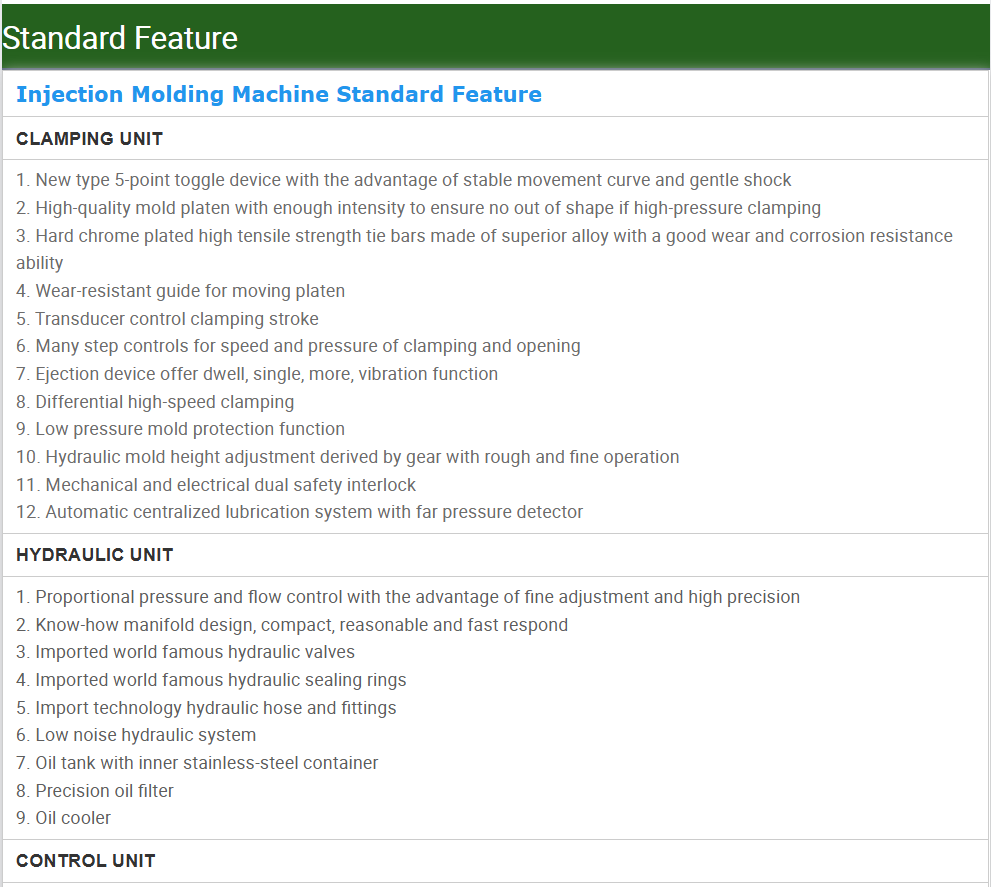

During the injection - molding stage, temperature control is an important factor in quality control. If the temperature is too high, the PET material may decompose, resulting in problems such as discoloration and brittleness of the product; if the temperature is too low, the fluidity of the material is insufficient, and it cannot evenly fill the mold, causing dimensional deviation and uneven wall thickness of the preform product. Therefore, by setting multiple temperature sensors in the heating barrel to precisely monitor the temperature at different positions and using advanced temperature - control algorithms, the temperature during the entire injection - molding process is ensured to be stable within an appropriate range. At the same time, the injection - molding pressure and injection speed also need to be strictly controlled. Appropriate injection - molding pressure can ensure that the material fills the mold cavity, and a stable injection speed helps to avoid the generation of vortex or jetting phenomena in the material, thereby ensuring the quality of the preform product.

The quality and maintenance of the preform mold also have a profound impact on product quality. The surface of the mold cavity needs to have a high degree of smoothness to ensure the surface quality of the preform product. Regular cleaning, polishing, and maintenance of the mold are essential. If there are scratches or wear on the surface of the mold cavity, flaws will appear on the surface of the preform product, affecting the appearance and performance of the product.

During the blow - molding stage, the precise control of the blowing pressure is the key. Excessively high blowing pressure will make the bottle wall too thin or even cause it to break; too low blowing pressure will result in a too - thick bottle wall or an incomplete bottle shape. Through high - precision pressure sensors and pressure - regulating valves, the blowing pressure is controlled within an appropriate range to ensure that the wall thickness of the bottle is uniform and meets the design requirements. The mold - closing accuracy of the blow - molding mold is also very important. Inaccurate mold - closing will cause problems such as flash and deformation of the bottle. Therefore, regular calibration and maintenance of the blow - molding mold are required.

In addition, the quality - monitoring system throughout the production process will monitor various production parameters and product quality indicators in real - time. For example, the dimensions, wall thickness, and weight of preform products and final products are inspected by online - monitoring equipment. Once a quality abnormality is detected, the system will send out an alarm in a timely manner, and operators can immediately take measures to adjust, such as modifying process parameters or replacing the mold, thereby ensuring the stability and consistency of product quality.