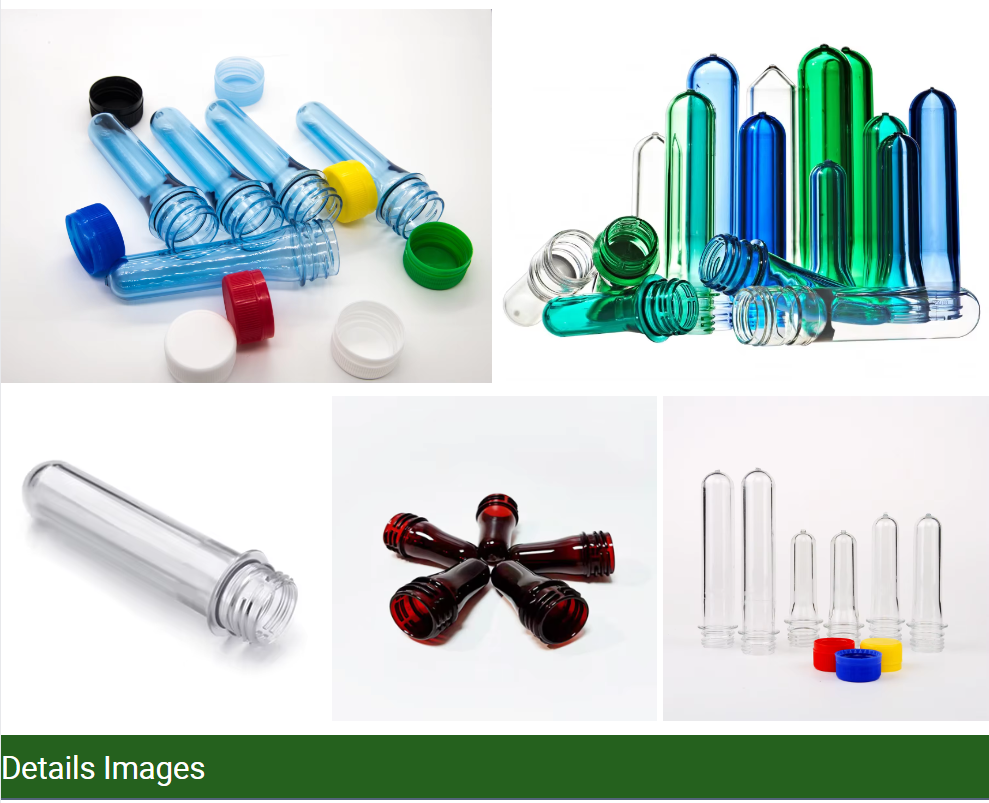

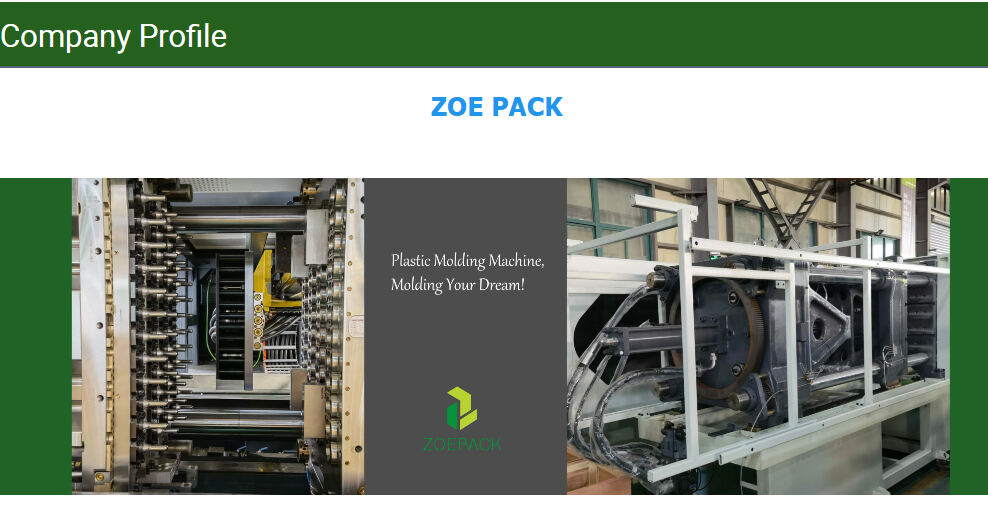

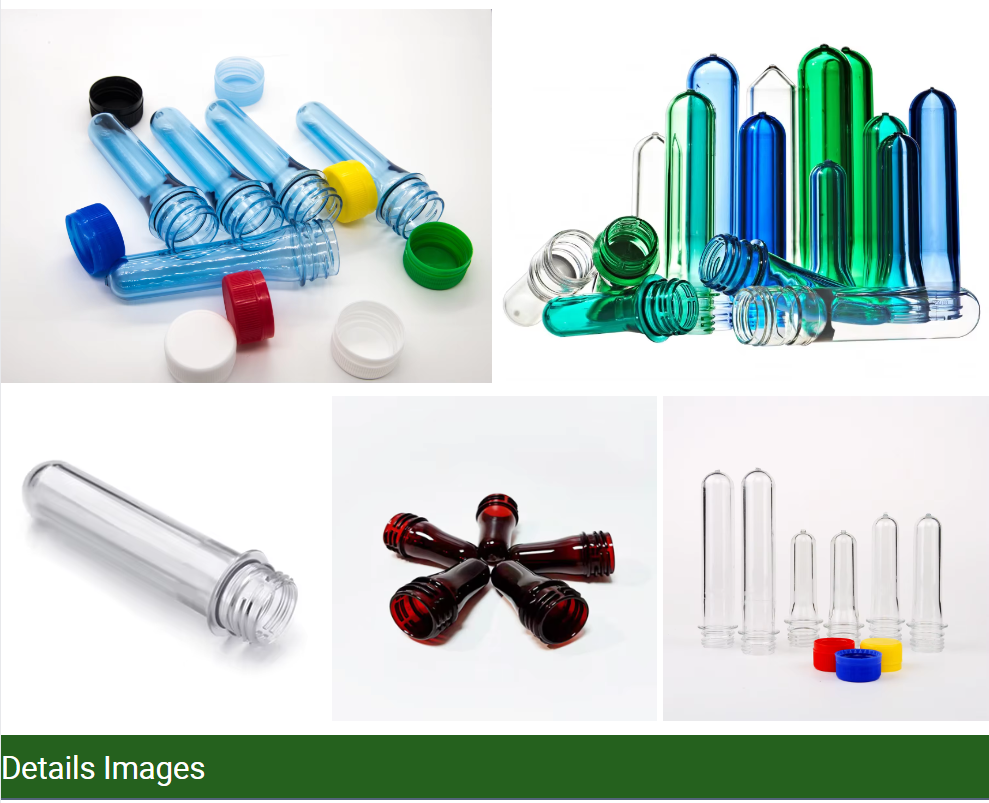

PET Preform Injection Molding Machine

The PET preform injection - blow molding machine has numerous remarkable technical advantages and performance characteristics, which make it occupy an important position in the field of plastic bottle production.

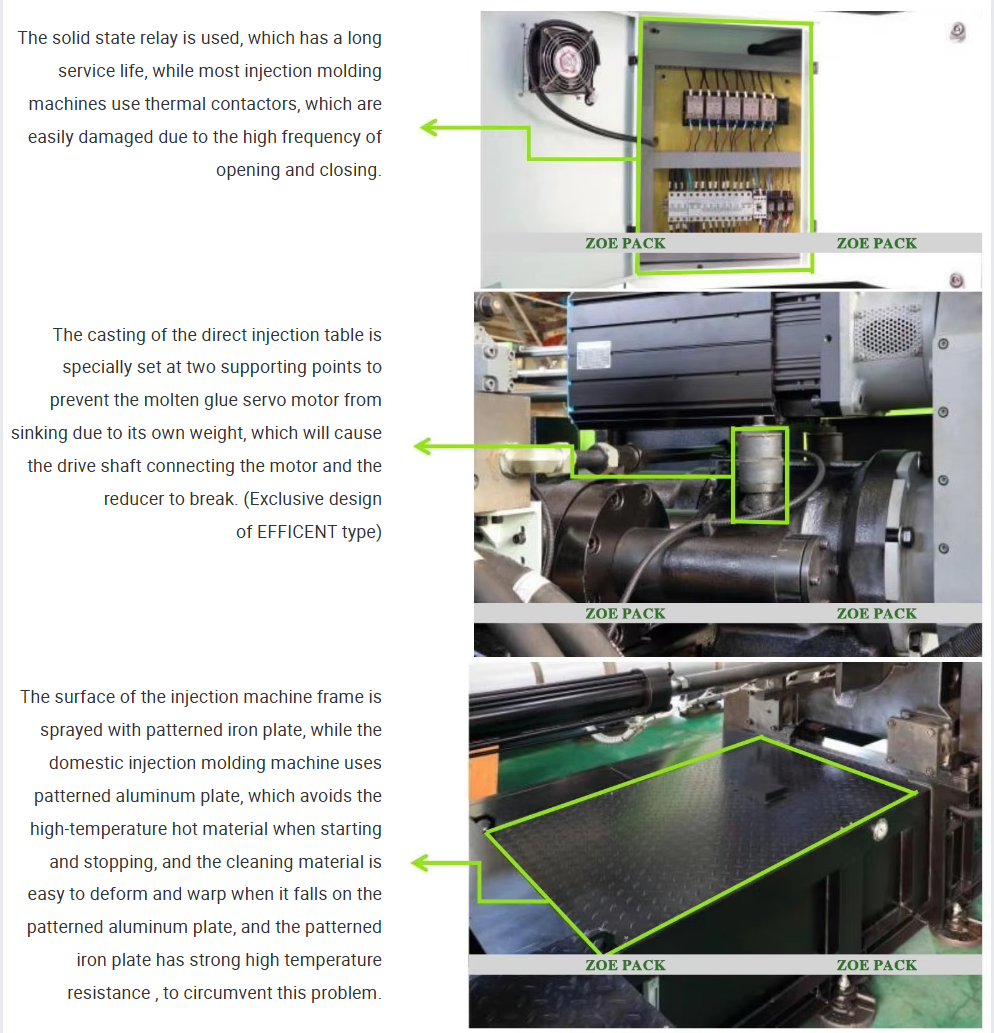

Firstly, it has high - precision forming ability. Since PET materials require precise shape control during injection - molding and blow - molding processes, this machine can achieve highly precise forming. During the injection - molding stage, through precise screw driving and temperature control, it can ensure that the PET material evenly fills the preform mold, thereby obtaining preform products with accurate dimensions and uniform wall thickness. During the blow - molding stage, the precise blowing pressure and mold - closing accuracy ensure that the final product can be formed strictly in accordance with the design requirements. Whether it is the outer shape curve of the bottle or the thickness distribution of the bottle wall, a high level of precision can be achieved. This high - precision forming ability makes the produced PET bottles have high consistency in appearance and quality, meeting the strict requirements of the modern packaging industry for product appearance and quality.

Secondly, it has high - efficient production efficiency. The PET preform injection - blow molding machine adopts advanced automation technology, which greatly shortens the production cycle. In the injection - molding process, the fast - heating and injection systems can complete the injection - molding of preform products in a short time. Moreover, the application of multi - cavity molds enables one injection to obtain multiple preform products, and then these products can quickly enter the blow - molding stage. The blow - molding process is also efficient. The stable blowing system and the rapid mold - opening and - closing actions ensure that products can be produced quickly. In addition, the automated operation of the machine reduces the time of human intervention and improves the overall production efficiency. This high - efficient production efficiency enables enterprises to produce a large number of PET bottles in a short time, meeting the large - scale demand for PET bottles in the market. For example, it can supply sufficient packaging bottles in time during the peak season of beverage production.

Thirdly, it has good material adaptability. Although mainly used for the processing of PET materials, this machine can also adapt to other similar thermoplastic materials to a certain extent. This is due to its adjustable heating system and screw design. For materials with different melting points and rheological characteristics, by adjusting the heating temperature and parameters such as the rotational speed and torque of the screw, a better plasticizing and forming effect can be achieved. This material adaptability broadens the application range of the machine, enabling enterprises to use the same machine when producing different types of plastic products, reducing equipment investment costs.

Fourthly, it has high - energy efficiency. Modern PET preform injection - blow molding machines focus on energy conservation in their design. For example, the heating system adopts high - efficiency heating elements and precise temperature - control algorithms, which can reduce unnecessary heat dissipation. During the injection - molding and blow - molding processes, through the optimized hydraulic system or electric - drive system, the power consumption is reduced. At the same time, some machines are also equipped with energy - recovery devices. For example, in the hydraulic system, the braking energy is recovered and converted into usable electrical energy or mechanical energy, further improving the energy - utilization efficiency of the machine. This not only helps to reduce the production cost of enterprises but also meets the requirements of energy conservation and environmental protection in modern society.