Mail Us: [email protected]

Call For Us: +86-512 58990369

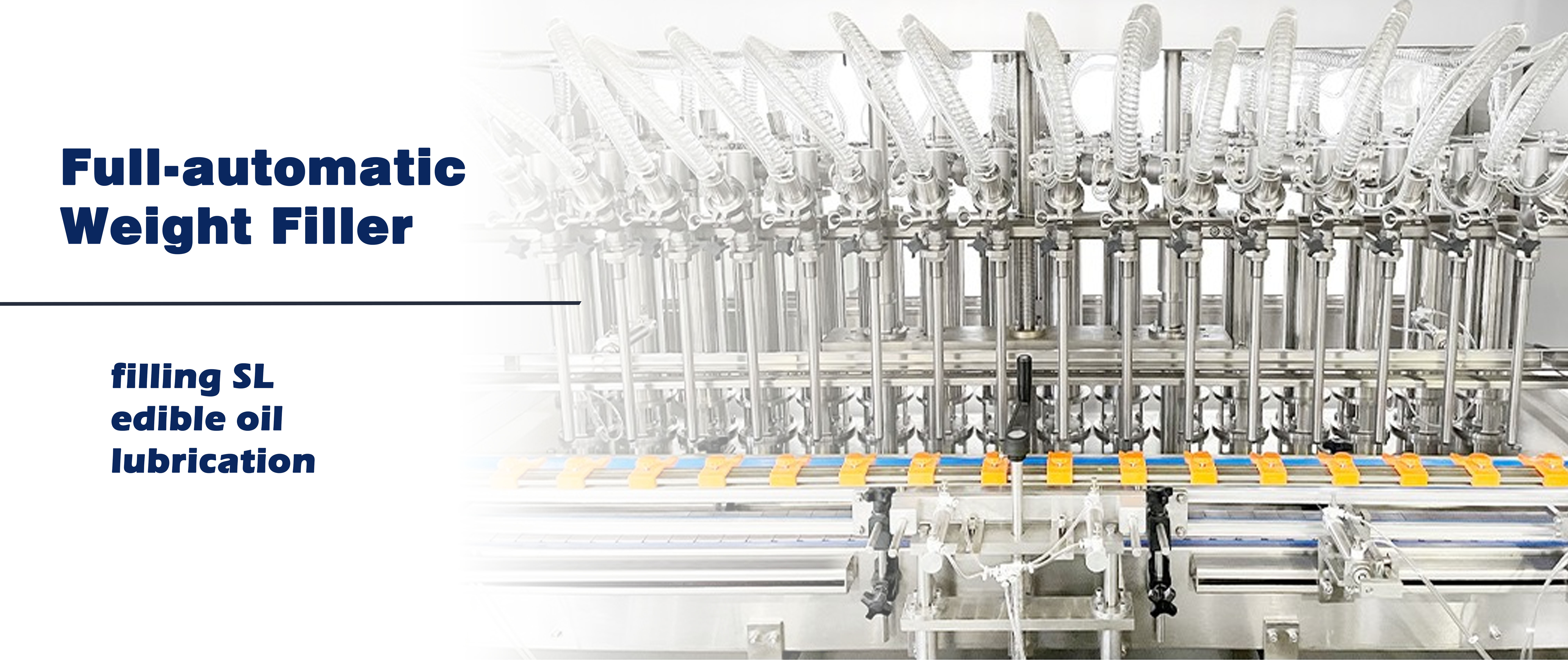

0.1-5L Cooking oil/Machine oil/Drinking oil |

||||||||||||||

Heads |

Suitable bottles |

Capacity(bottle/hour) |

Precise |

Size of Machine(mm) |

Power(kW) |

Power source |

Air source |

|||||||

4 Heads |

Can be customized |

500m≤1200BPH |

≤0.5% |

1600*1300*2200 |

3KW |

220/380V;

50/60Hz

(Can be customized)

|

0.6-0.8MPa |

|||||||

6 Heads |

500m≤1600BPH |

1800*1300*2200 |

3KW |

|||||||||||

8 Heads |

500m≤2500BPH |

2000*1300*2200 |

3KW |

|||||||||||

12 Heads |

500m≤3000BPH |

2400*1300*2200 |

3.5KW |

|||||||||||

16 Heads |

500m≤4000BPH |

2400*1400*2200 |

3.5KW |

|||||||||||

20 Heads |

500m≤5000BPH |

2600*1400*2200 |

3.5KW |

|||||||||||

5-20L Oil Jerry Can |

||||||||||||

Type |

Suitable bottles |

Capacity |

Machine Size |

Power |

Power Supply |

Precise |

||||||

2 Heads |

length:360-3600mm

width:100-300mm

height:250-500mm neck

diameter:≥Φ40mm

(can be customized)

|

≤0.5% |

2000*1700*2300mm |

2KW |

AC220/380V

50-60Hz

|

≤±0.5% |

||||||

4 Heads |

2500*1700*2300mm |

2KW |

||||||||||

6 Heads |

3500*1700*2300mm |

2KW |

||||||||||

8 Heads |

4500*1700*2300mm |

2.5KW |

||||||||||

Main Configuration |

||||||

No. |

Name |

Place of origin |

Brand |

|||

1 |

PLC |

Japan |

Mitsubishi |

|||

2 |

Weight Sensor |

Germany |

HBM |

|||

3 |

Angle seat Valve |

Taiwan |

AIRTAC |

|||

4 |

Solenoid Valve |

Taiwan |

AIRTAC |

|||

5 |

Photo Sensor |

Germany |

SICK |

|||

6 |

Touch screen |

Japan |

WEINVEIW |

|||

7 |

Diving cylinder |

Taiwan |

AIRTAC |

|||

8 |

Power button |

France |

Schneider |

|||

9 |

Button |

France |

Schneider |

|||

10 |

Magnetic switch |

Taiwan |

AIRTAC |

|||

11 |

oil-water separator |

Taiwan |

SHAKO |

|||

Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide 24 HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about 60 days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 months warranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's ZOE PACK's advantage? ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support! |

ZOEPACK

Brings you the best Automatic Linear Chili Sauce Tomato Sauce Paste Filler Plastic Jar Bottle Piston Filling Machine Packing Line. This incredible machine is the perfect solution for those who are looking for a reliable and efficient way to fill plastic jars and bottles with sauces and pastes.

This filling machine is good for high-speed production lines have real profit fill up to 200 containers each and every minute. It really is made to be effortless to work with and keep, with a interface this is certainly user-friendly allows operators to easily adjust settings and monitor the filling process.

The equipment is made out of top-quality materials to make sure dependability and durability, which makes it well suited for use within busy production facilities. It features a fully-automatic linear design, this implies once it is set up and running that it needs minimal operator intervention.

The filling device also includes a piston system this is certainly filling which ensures accurate and consistent filling of every container. This method is specially created to manage dense and sauces that are viscous pastes, ensuring they are filled accurately and without spills.

The Automatic Linear Chili Sauce Tomato Sauce Paste Filler Plastic Jar Bottle Piston Filling Machine Packing Line is also versatile, allowing it to be properly used having a variety is wide of container shapes and sizes. This may make it well suited for use within a variety of different companies, including food and beverages, cosmetics, and pharmaceuticals.

Why wait any longer? Invest in the best and see the difference in your production process with ZOEPACK's Automatic Linear Chili Sauce Tomato Sauce Paste Filler Plastic Jar Bottle Piston Filling Machine Packing Line.

Please feel free to let us know if you need any help,we will provide a professional guidance for youl

CONTACT US