Mail Us: [email protected]

Call For Us: +86-512 58990369

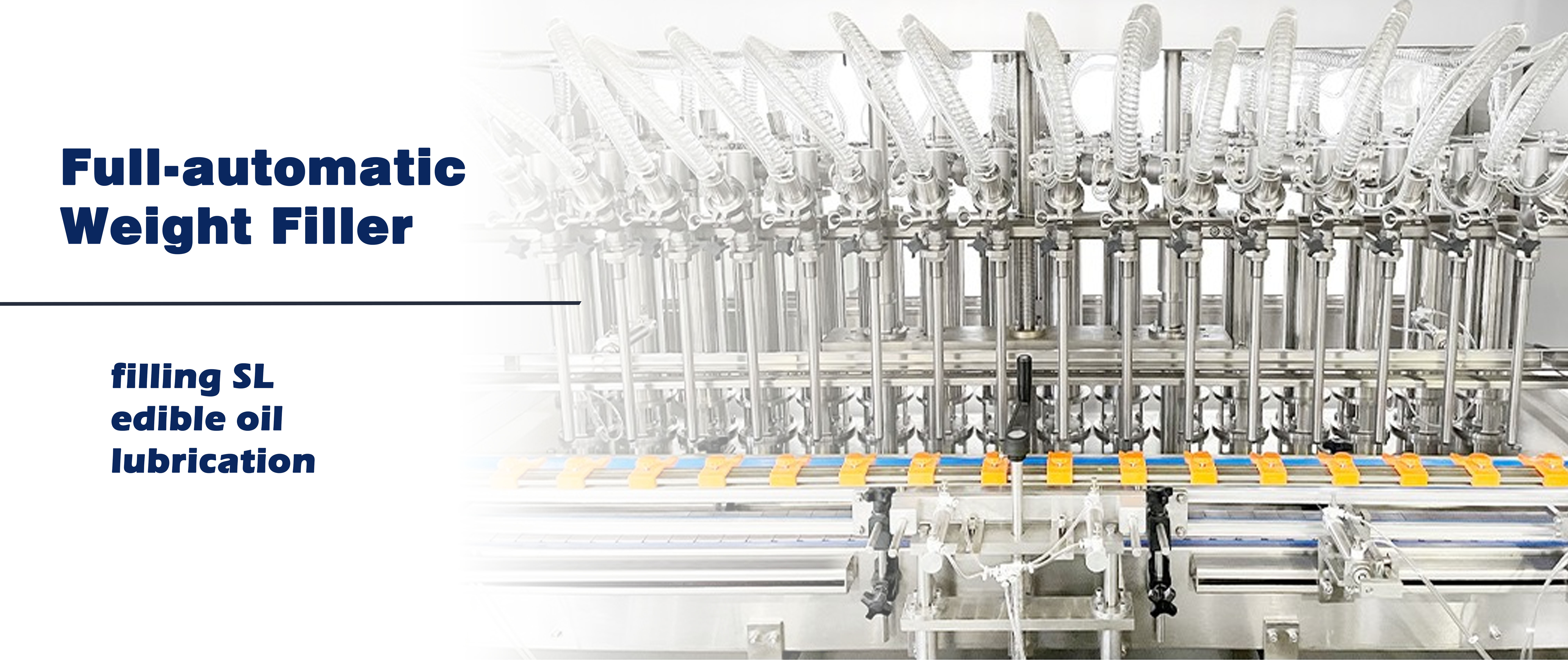

0.1-5L Cooking oil/Machine oil/Drinking oil |

||||||||||||||

Heads |

Suitable bottles |

Capacity(bottle/hour) |

Precise |

Size of Machine(mm) |

Power(kW) |

Power source |

Air source |

|||||||

4 Heads |

Can be customized |

500m≤1200BPH |

≤0.5% |

1600*1300*2200 |

3KW |

220/380V;

50/60Hz

(Can be customized)

|

0.6-0.8MPa |

|||||||

6 Heads |

500m≤1600BPH |

1800*1300*2200 |

3KW |

|||||||||||

8 Heads |

500m≤2500BPH |

2000*1300*2200 |

3KW |

|||||||||||

12 Heads |

500m≤3000BPH |

2400*1300*2200 |

3.5KW |

|||||||||||

16 Heads |

500m≤4000BPH |

2400*1400*2200 |

3.5KW |

|||||||||||

20 Heads |

500m≤5000BPH |

2600*1400*2200 |

3.5KW |

|||||||||||

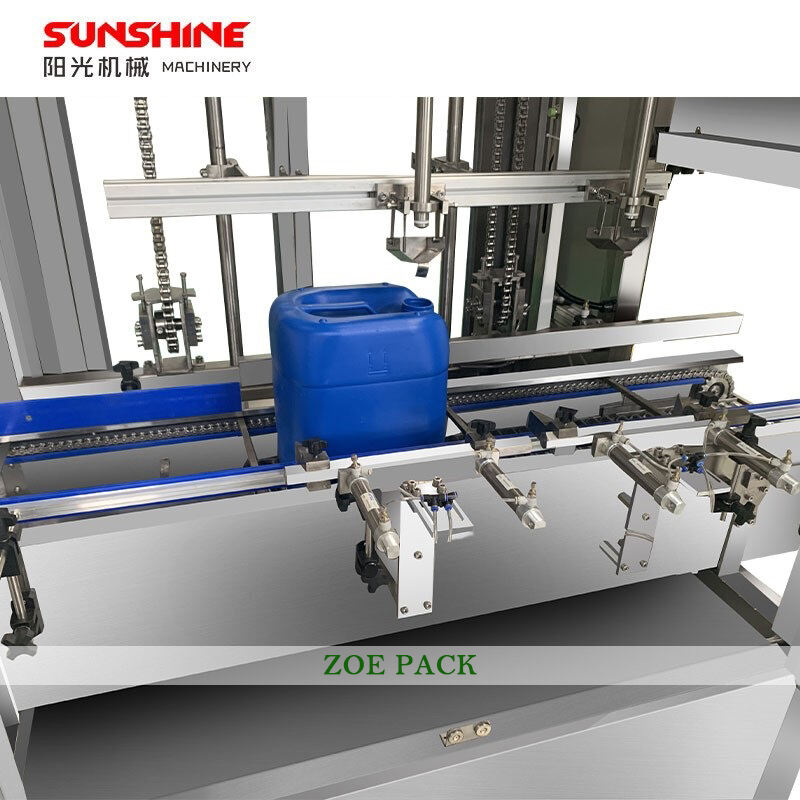

5-20L Oil Jerry Can |

||||||||||||

Type |

Suitable bottles |

Capacity |

Machine Size |

Power |

Power Supply |

Precise |

||||||

2 Heads |

length:160-3600mm

width:100-300mm

height:250-500mm neck

diameter:≥Φ40mm

(can be customized)

|

≤0.5% |

2000*1700*2300mm |

2KW |

AC220/380V

50-60Hz

|

≤±0.5% |

||||||

4 Heads |

2500*1700*2300mm |

2KW |

||||||||||

6 Heads |

3500*1700*2300mm |

2KW |

||||||||||

8 Heads |

4500*1700*2300mm |

2.5KW |

||||||||||

Main Configuration |

||||||

No. |

Name |

Place of origin |

Brand |

|||

1 |

PLC |

Japan |

Mitsubishi |

|||

2 |

Weight Sensor |

Germany |

HBM |

|||

3 |

Angle seat Valve |

Taiwan |

AIRTAC |

|||

4 |

Solenoid Valve |

Taiwan |

AIRTAC |

|||

5 |

Photo Sensor |

Germany |

SICK |

|||

6 |

Touch screen |

Japan |

WEINVEIW |

|||

7 |

Diving cylinder |

Taiwan |

AIRTAC |

|||

8 |

Power button |

France |

Schneider |

|||

9 |

Button |

France |

Schneider |

|||

10 |

Magnetic switch |

Taiwan |

AIRTAC |

|||

11 |

oil-water separator |

Taiwan |

SHAKO |

|||

Q: Can we visit your factory? Sure. We located in Zhangjiagang city which is very near Shanghai. For overseas customers, you can fly to Shanghai Pudong International Airport. We can pick you up in the Airport. (or Hongqiao International Airport. ) We also provide visit online by video. Q: How can we get the exact price of plastic machine? Contact us with the products size, shape, annual quantity and photo if possible. We can recommend our machine models with quotation. Q: Do you provide any spare parts with machine? Yes, we offer all necessary spare parts before shipment.(contact us for packing list ) Q: How about your after-sale service ? We offer manual instruction and engineer training before loading,after shipment we provide24HRS online support, video technical support or field installation assist. Q: What is the lead time? For customized machine, it takes about60days after deposit. For stock machine, fast shipment. ( The actual production cycle will vary according to the degree of customization.) Q: What is the warranty period for your machine ? 12 monthswarranty for components and technical support . Q: Do you provide custom machines? Most of our machines are customized. Our goal is efficiency and stable performance. We design the machines according to customers products to meet customer' needs. Q: How can we install the machine when it arrives? We can send experienced technicians to customer's country for guiding the installation and commission the machine, also train the customer's employees. Q: What's ZOE PACK's advantage? ZOE PACK provide customers with turnkey projects. Including plant design, plastic machine and mold installation, debugging, also we can source the auxiliary equipment for customers. We can ship the full set of machines after testing in our factory. It will save a lot of cost and time. ZOE PACKwill be your reliable friend in China, and we will always do our best to give you max support! |

ZOEPACK

Introducing the High Speed Automatic Engine Motor Oil Bottle Filling and Packing Machine. This powerful and efficient machine is designed to handle your car lubricant oil packing needs with ease. It can fill bottles up to 1L, 3L, and 5L in size.

Featuring technology is innovative state-of-the-art machinery, this machine is by using the ability of filling up to 2500 bottles each hour. This operation is high-speed enhances productivity by helping you save a while cash while ensuring you meet your production goals. It is perfect to be used in large-scale production facilities, warehouses, and factories.

Created with reliability and productivity in your mind. It uses materials and that can be high-quality ensure it could handle the absolute most challenging of industrial environments. Additionally, its size is compact makes easy to maneuver around, install, and keep maintaining.

Applying this machine is fairly easy. Simply load the bottles on the conveyor belt and invite the machine perform some rest. It comes with automated fluid technology is filling ensures the bottles are filled to the precise volume that you want. The device also contains sensors that detect bottle positioning and fill volumes. Additionally, it could also be effortlessly programmed to fill bottles with various volumes.

At ZOEPACK, we have been invested in quality that gives that meet your requirements. This is exactly why every part of the machine is created using the quality materials which are highest and under strict quality control standards. This means that the tall Speed automated Engine Motor Oil Bottle Filling and Packing Machine is accurate, reliable, and efficient.

Features advanced security precautions to guard your workers in terms of security. It comes down with an stop is automatic when the equipment detects any abnormalities or missing bottles. The device also contains a security address that keeps employees protected while in operation.

Get in touch with us today to order and experience the benefits of this High Speed Automatic Engine Motor Oil Bottle Filling and Packing Machine from ZOEPACK.

Please feel free to let us know if you need any help,we will provide a professional guidance for youl

CONTACT US