Production Description

ZOE PACK

Injection Molding Machine

Specialized for making PET preforms , caps , pails, buckets, jars, covers, lids. Special screw for PET products, all machine adapt latest Taiwan control system, Japan YUKEN hydraulic valve for highest quality standard and machine performance. We also able to provide mould designing and manufacturing to help you build up all kinds of plastic items manufacturing.

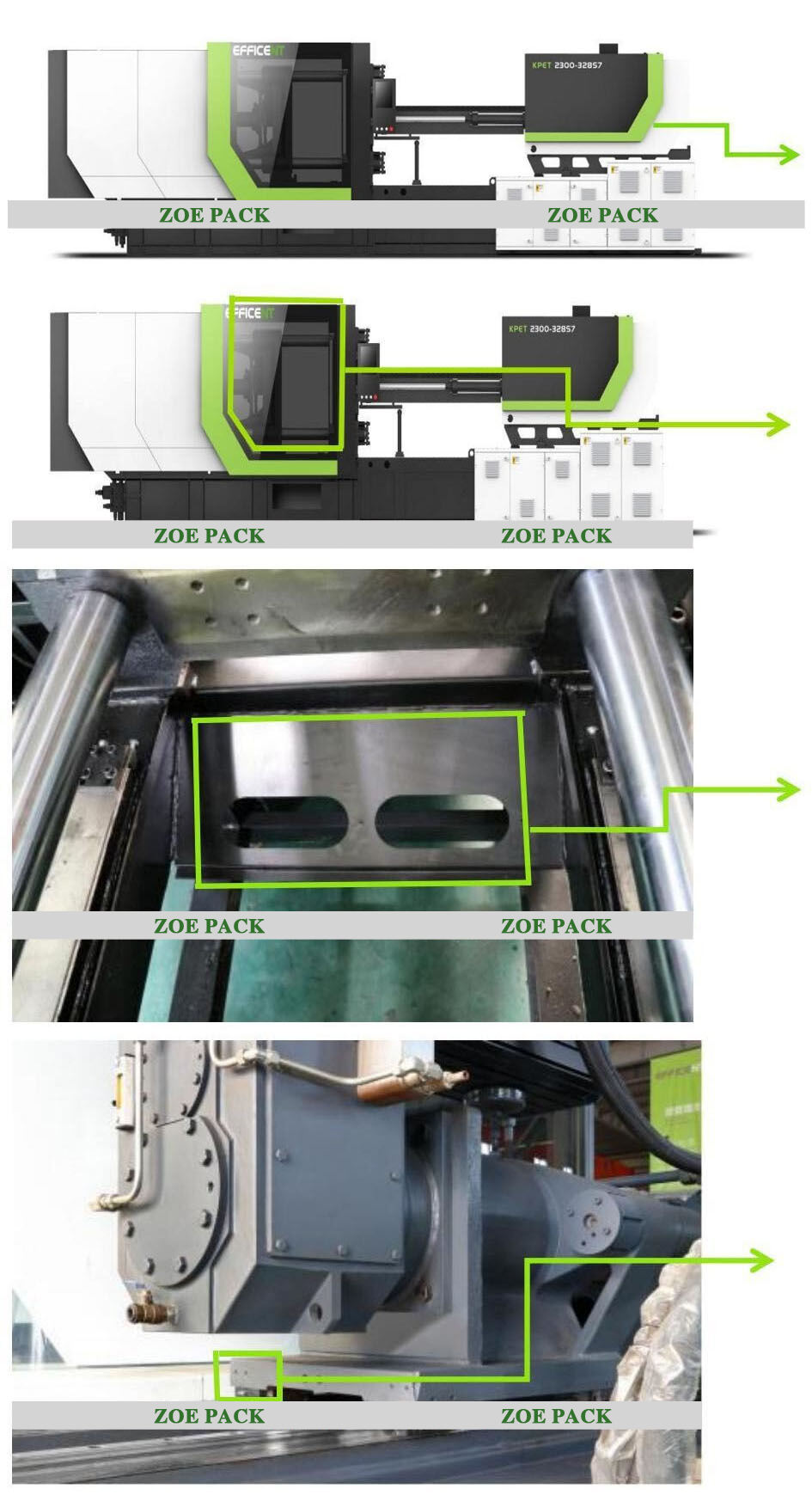

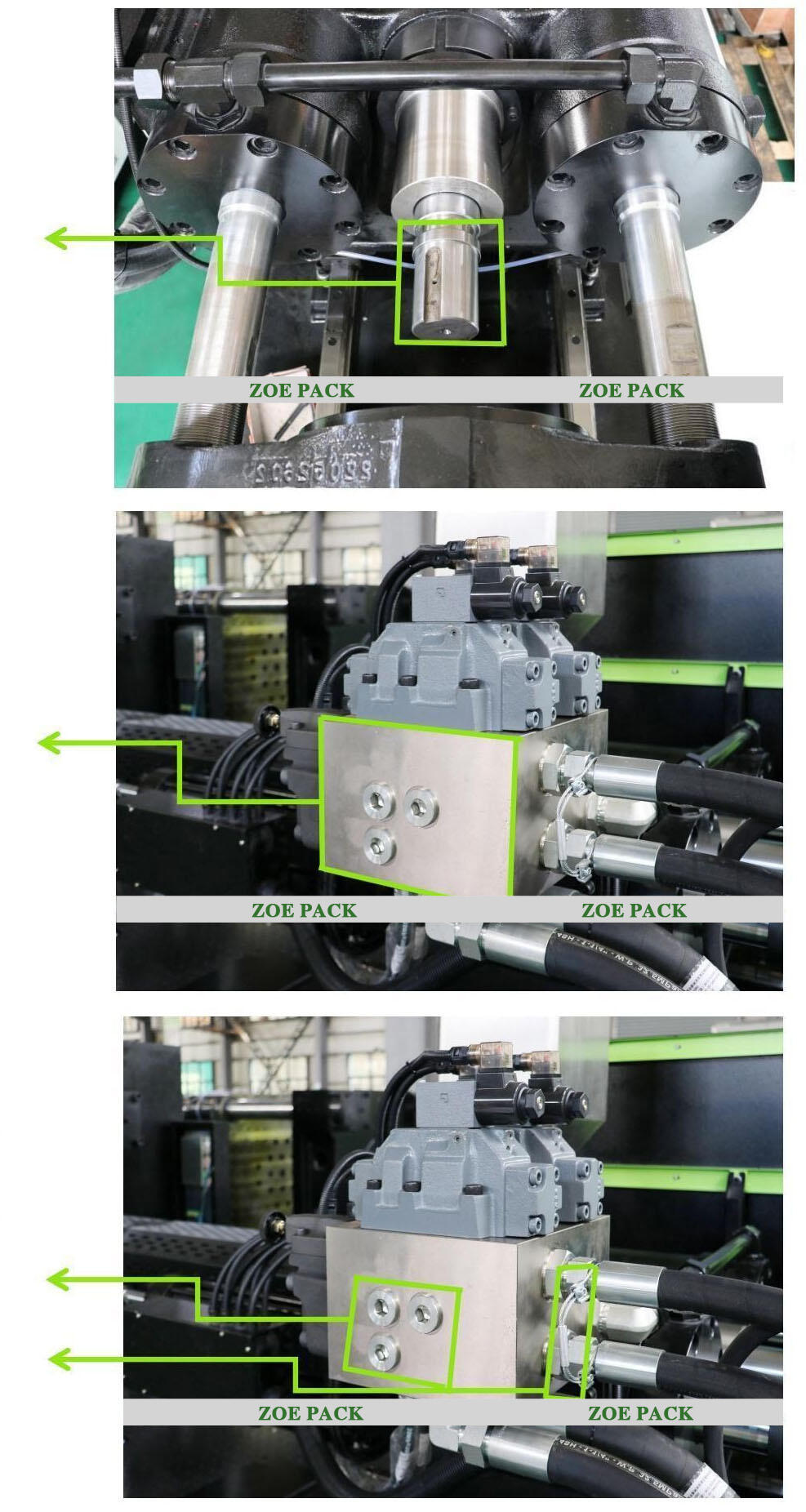

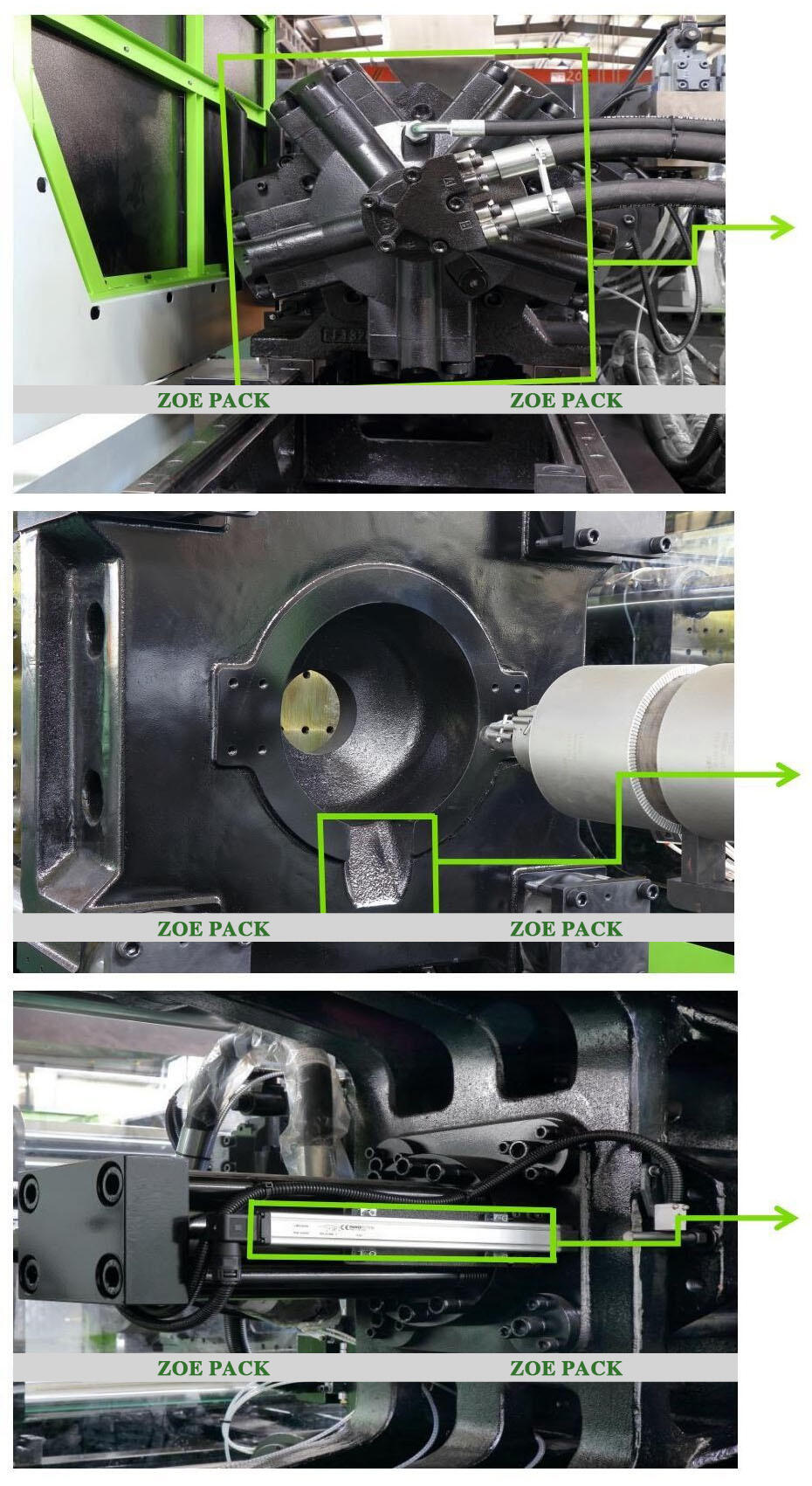

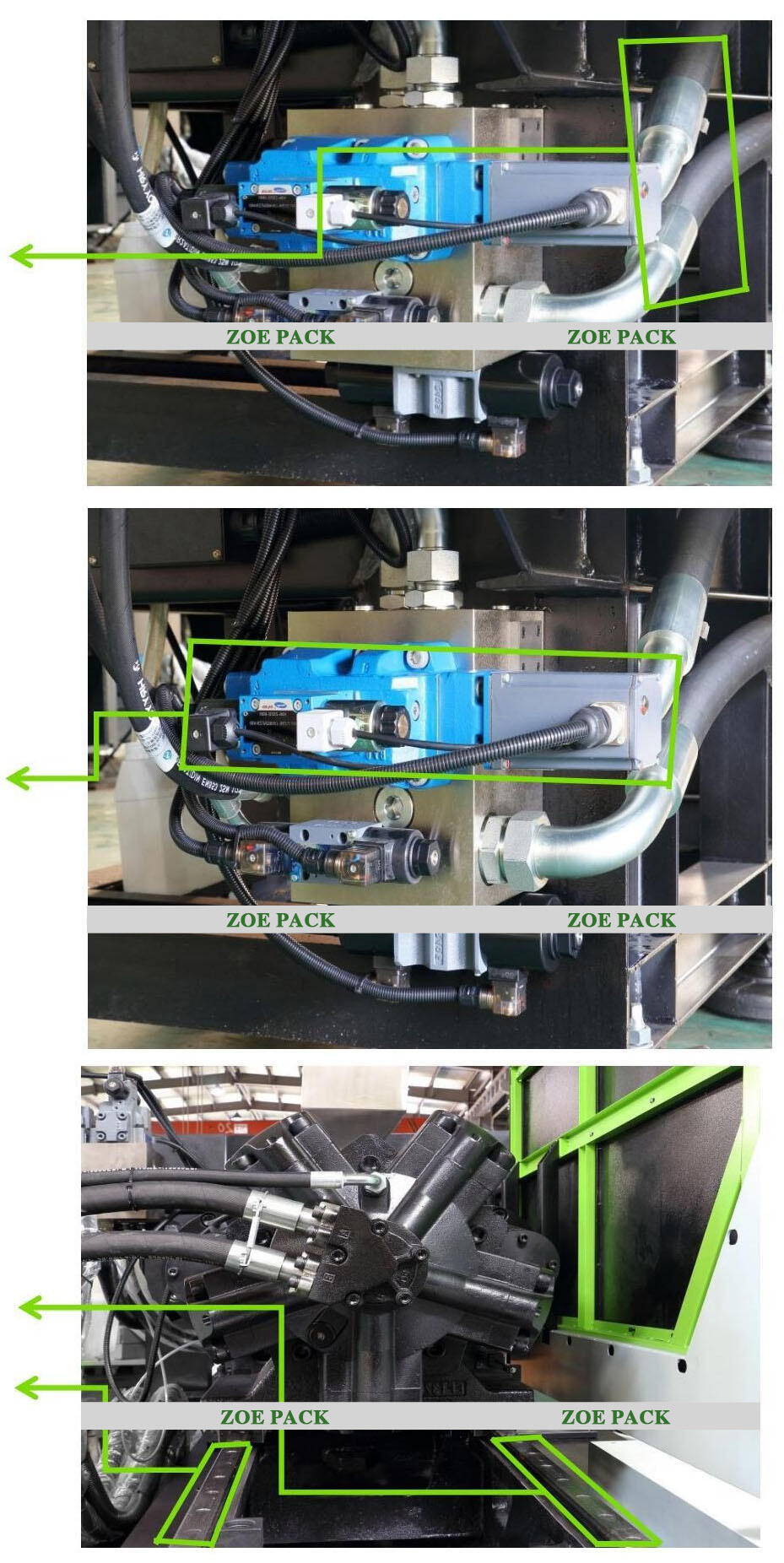

Details Images

Oil-electric hybrid high-speed preform injection molding machine.Special injection molding machine for fast preform.The whole

machine adopts the design style of European style, and the appearance is beautiful and high-end.

The safety door glass is made of PC board material, which has good strength and high transparency, while most of the injection

molding machines in the same industry use acrylic board, which has poor strength, vulnerable parts, and poor transparency.

The blanking plate is heightened with two water pipe perforations, which is convenient for connecting the water inlet and outlet

pipes

of the mould.

For models above 320 tons, the base of the pallet is lengthened to allow the weight of the reducer to be distributed on the base.

Otherwise, the reducer of a large preform machine is heavy and the weight is distributed on the drive shaft, which is easy to

deform and break. (Exclusive design of EFFICENT type)

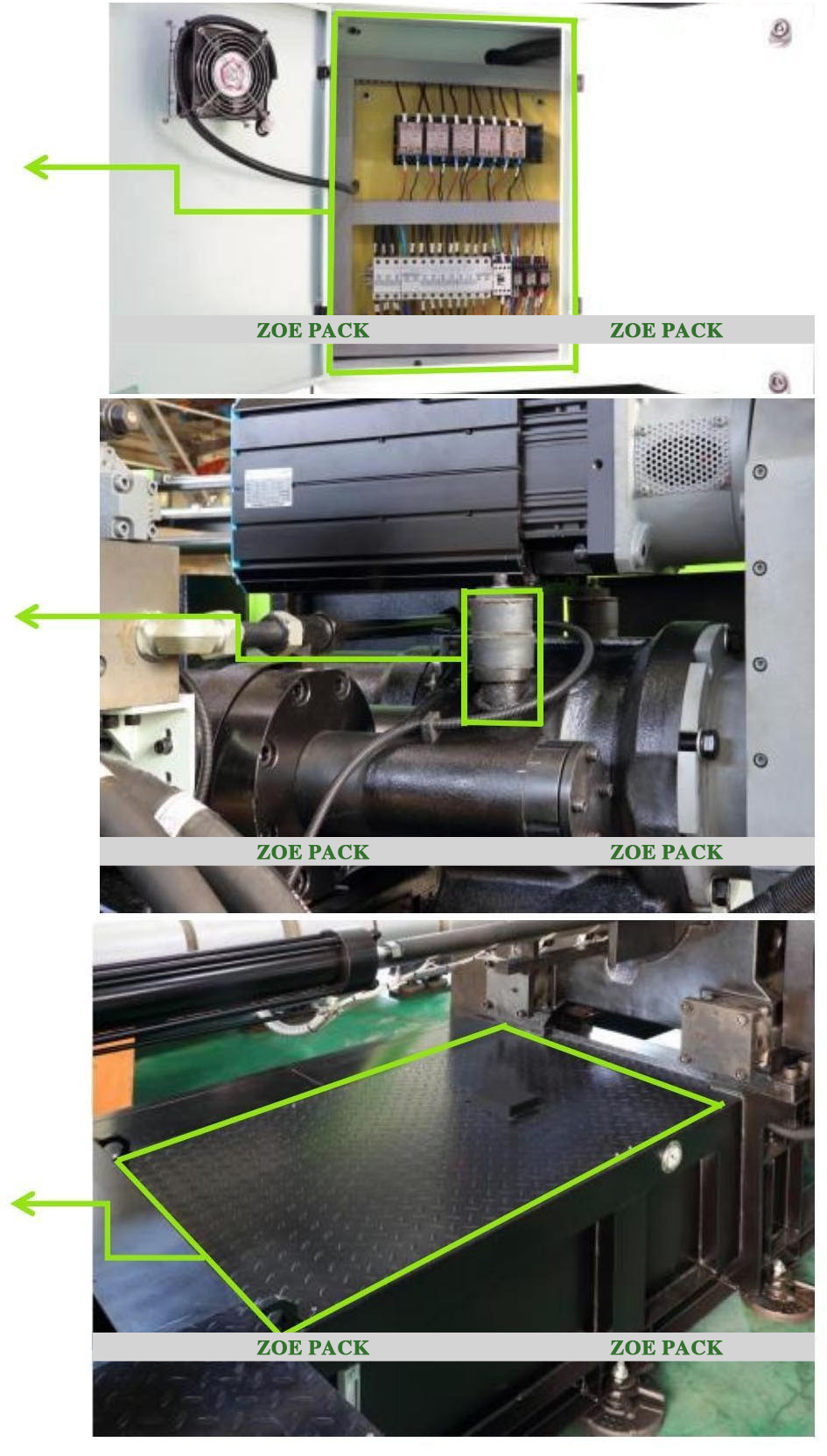

The solid state relay is used, which has a long service life, while most injection molding machines use thermal contactors, which are

easily damaged due to the high frequency of opening and closing.

The casting of the direct injection table is specially set at two supporting points to prevent the molten glue servo motor from

sinking due to its own weight, which will cause the drive shaft connecting the motor and the reducer to break. (Exclusive design

of EFFICENT type)

The surface of the injection machine frame is sprayed with patterned iron plate, while the domestic injection molding machine uses

patterned aluminum plate, which avoids the high-temperature hot material when starting and stopping, and the cleaning material is

easy to deform and warp when it falls on the patterned aluminum plate, and the patterned iron plate has strong high temperature

resistance , to circumvent this problem.

The double-injection structure is adopted to ensure the stability of the forward and backward movements of the injection platform.

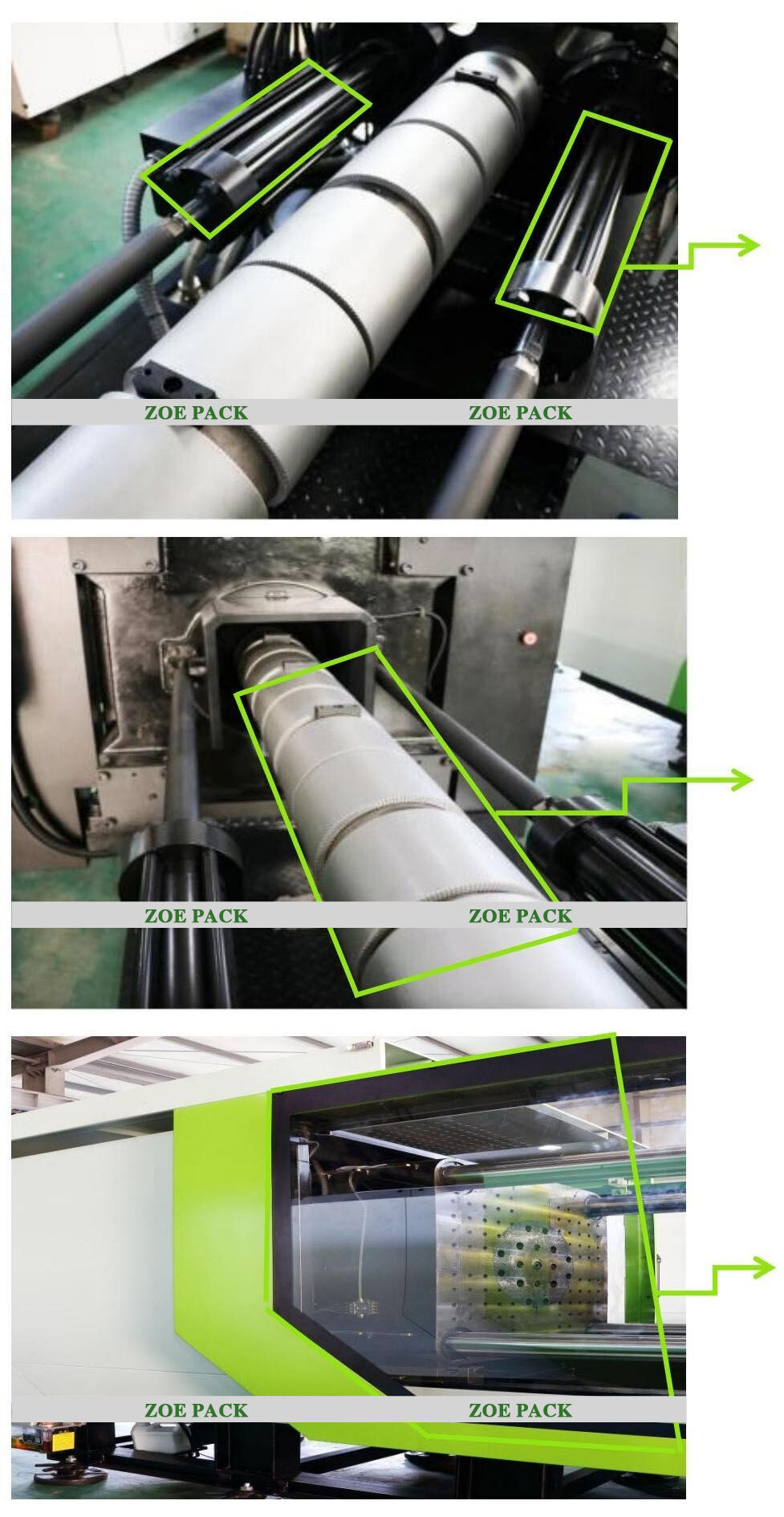

The standard high-quality ceramic heating ring has good heat preservation effect, avoids large temperature deviation from

affecting

the PET bottle preform molding process, and has a long service life.

Between the safety door sheet metal and the pc transparent board, a special UV process is used, and a black frame is added around

it to increase the overall aesthetics. (Exclusive design of EFFICENT type)

Because PET preforms are formed, the screw is long and the torque is large, and the tail of the screw is prone to twisting (the

probability of breaking is high in the same industry), so the special design of the screw tail of EFFICENT has a longer and

thicker structure to avoid the problem of twisting of the screw tail.

Each oil plate of Ifite is treated with plating process, and the surface finish is good, while most of the injection molding machine

industry adopts simple painting method, which is low-grade and unsightly.

The oil pipe and the oil plate are all connected by high-precision G thread method, which has high precision and avoids the problem of oil leakage. However, most of the same industry use raw tape straight thread, because the use of raw tape to enhance the sealing method is easy to cause accidents. Oil leakage caused by the degree of looseness caused by the personal factors of the assembly workers, and the white raw tape is exposed and unsightly.

Using a specially customized high-torque motor for PET, the motor model of the screw of the same type of EFFICENT type is one or

two larger than that of the same industry, ensuring sufficient torque and melting speed. And it ensures lower melt pressure and

prolongs the service life of the motor, while the frequency of motor damage due to excessive melt pressure in the same industry is

very high.

The material cleaning port is specially designed under the front plate of the clamping structure, which is very convenient for

material cleaning. (Exclusive design of EFFICENT type)

The opening and closing molds, thimbles, glue injection, and electronic rulers all use imported top brand German NOVO to ensure

the control accuracy of each operation, while 90% of the manufacturers in the same industry use domestic electronic rulers with

international brands.

The opening and closing molds go to the oil passage, the inlet and outlet oil pipes, the oil plate and the valve diameter are one or two grades larger than those in the same industry, ensuring sufficient mold opening and closing speed, and the opening and closing speed is 40%~60% faster than the same model in the same industry

The mold opening and closing operation of 320 tons and above models is equipped with servo proportional valve structure as standard,

with fast mold opening and closing speed and high repeatability, while the injection molding machines in the same industry all adopt directional valve structure, slow mold opening and closing speed, large position deviation, proportional valve The cost is more than 12,000 yuan, while the directional valve is only more than 900

The injection platform adopts a dual linear guide rail structure with zero resistance, which ensures a faster injection speed, while the traditional injection molding machine adopts a guide rod structure, which has high resistance and slow injection.

The oil tank is specially designed, narrow inside and wide outside, avoiding the preform falling into the oil tank during the free

fall process, rebounding to the lower hopper after sticking to the oil, and making the whole preform into waste after mixing with

other clean preforms. (Exclusive design of EFFICENT type)

Using high-speed preform machine with high rigidity speed, the mold opening and closing speed is 40%~60% faster than that of

preform machines in the same industry (taking 320 tons as an example, the mold opening and closing cycle in the same industry is 3.5~4.1

seconds, and EFFICENT type only needs 2.0~ 2.3 seconds).

The base of the injection platform adopts three-point positioning on one side to fully ensure the stability of the base. All models in

the same industry adopt two-point positioning on one side.

There are many nozzle aperture specifications, including 5.5mm, 8mm, 10mm, 12mm, 16mm, and 20mm, but the assembly dimensions of

the tail of the nozzle are all common, which is convenient for customers.

Model exchange

Standard Feature

Injection Molding Machine Standard Feature |

CLAMPING UNIT |

1. New type 5-point toggle device with the advantage of stable movement curve and gentle shock |

HYDRAULIC UNIT |

1. Proportional pressure and flow control with the advantage of fine adjustment and high precision |

CONTROL UNIT |

1. The computer is imported from Industry family. The LCD displaying screen with high clarity has Chinese and English |

SPARE PARTS |

█ Operation Manual █ Normal hopper |

More Injection Molding Machine Applications

Injection Molding Machine Applications |

Medical Appliance Auto Parts Packaging Electronic Products Optical Element House ware Building Components |

|

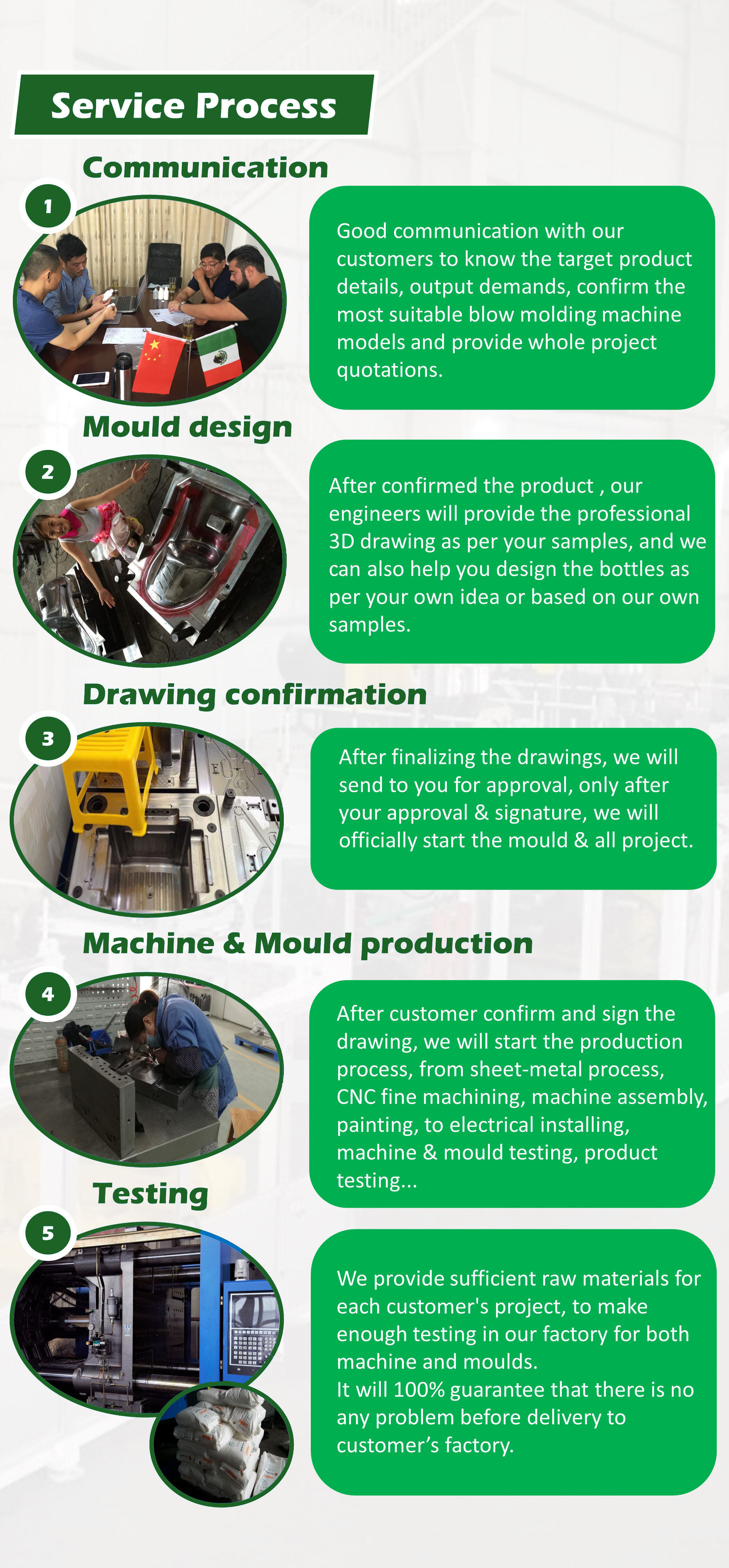

Company Profile

ZOE PACK

ZOE PACK

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery, injection molding machine, blow molding machine, PET blow molding machine, injection blow molding machine, during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging machinery, to update the technology, to learn advanced experience,to confirm new theory and new design, we are forming a unique competitive advantage of our owns.The machines from our company carry good quality and effective after-sales service, upon the market,

customers from more than 45 countries, we provide complete solution for your plastic industry business, as well as all sorts of technical support & after-sale services!

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!

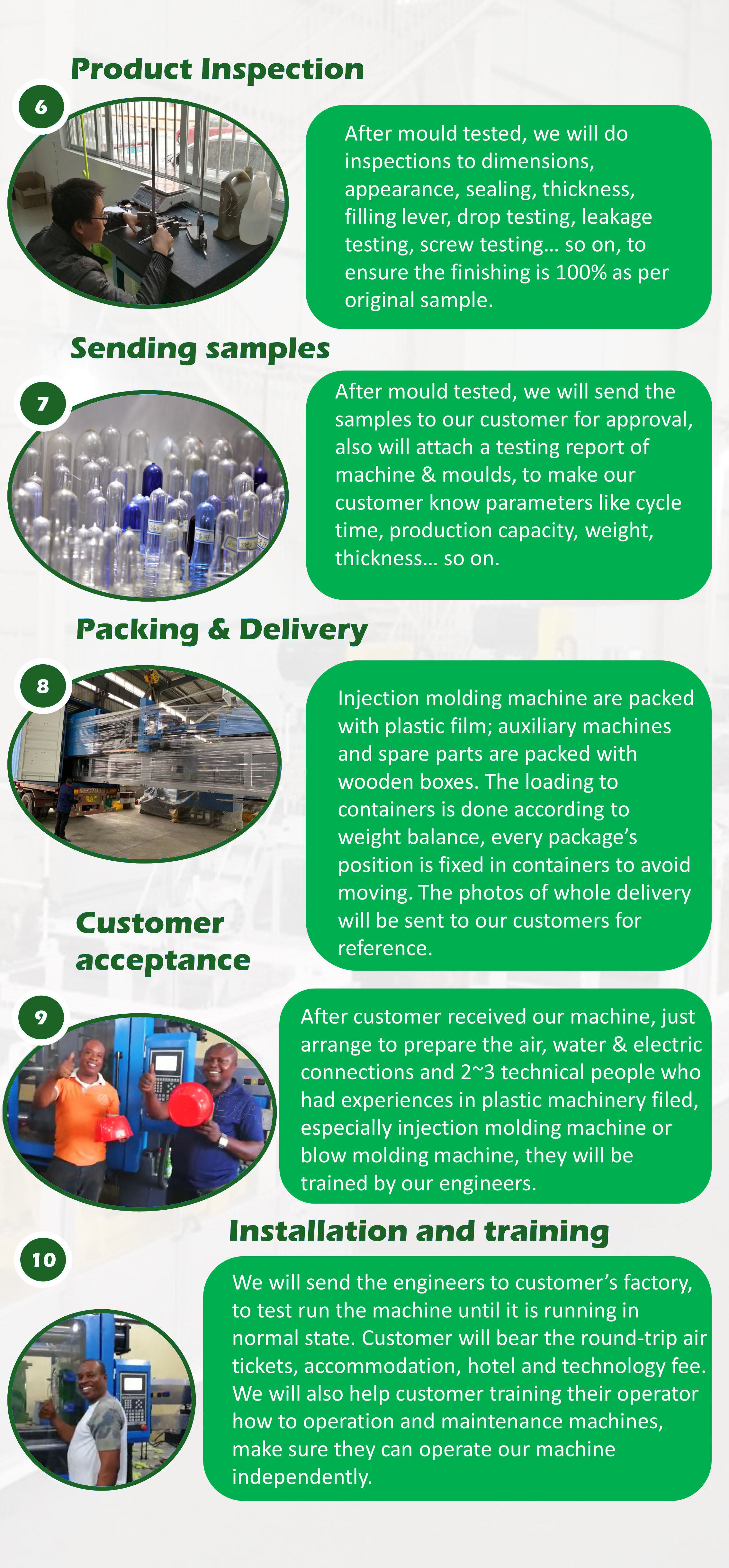

Our Service

FAQ |

|

ZOEPACK

The High-Speed Efficiency Plastic PET Injection Molding Machines Preform Making is a top-quality solution for clients whom require high efficiency and effectiveness with regards to synthetic injection molding. PET preform making has become easier with this specific advanced product which utilizes technology advanced to produce high-quality products.

Constructed from strong and durable materials the ZOEPACK molding machine is made to withstand the test of the time and heavy handle use. The item's surface is not resistant to wear and tear but additionally smooth, making it easier to scrub and keep maintaining.

The molding machine's high-speed efficiency means that the preforms produced are of high precision, meeting the customer's requirements. Additionally, the production speed is faster, which ultimately ensures that the apparatus can produce more preforms in less time. This effectiveness in time high-speed general production costs while delivering top-quality products and services.

One of the options notables with ZOEPACK's High Speed Efficiency Plastic PET Injection Molding Machines Preform Making is its simple operation. The equipment is user-friendly, its simple and intuitive program that operators can get a grip on and navigate the equipment with simplicity. The device's ergonomic design helps to make sure operators can work for long hours without feeling fatigued.