Company Profile

Zoe Pack(suzhou) CO.,Ltd.

We are a professional food and beverage machinery manufacture. ZOE PACK has its own special advantages in the research, design and manufacture and offers technical support to customers. We provide perfect after-sales service.

Our Beverage Machinery includes carbonated soft drink production lines; none-areated beverage bottled filling production lines and juice / tea beverage / wine bottled / barreled filling production lines. You are welcome to cooperate with us.

This series of bottle water production lines are mainly used for the Non-Aerated drink such as mineral water, pure water, non-gas wine drink and so on, with optional capacity from is 2000BPH based on 200ml to 2000ml.

Technical Parameters

0.1-5L Cooking oil/Machine oil/Drinking oil | ||||||||||||||

Heads | Suitable bottles | Capacity(bottle/hour) | Precise | Size of Machine(mm) | Power(kW) | Power source | Air source | |||||||

4 Heads | Can be customized | 500m≤1200BPH | ≤0.5% | 1600*1300*2200 | 3KW | 220/380V; 50/60Hz (Can be customized) | 0.6-0.8MPa | |||||||

6 Heads | 500m≤1600BPH | 1800*1300*2200 | 3KW | |||||||||||

8 Heads | 500m≤2500BPH | 2000*1300*2200 | 3KW | |||||||||||

12 Heads | 500m≤3000BPH | 2400*1300*2200 | 3.5KW | |||||||||||

16 Heads | 500m≤4000BPH | 2400*1400*2200 | 3.5KW | |||||||||||

20 Heads | 500m≤5000BPH | 2600*1400*2200 | 3.5KW | |||||||||||

5-20L Oil Jerry Can | ||||||||||||

Type | Suitable bottles | Capacity | Machine Size | Power | Power Supply | Precise | ||||||

2 Heads | length:360-3600mm width:100-300mm height:250-500mm neck diameter:≥Φ40mm (can be customized) | ≤0.5% | 2000*1700*2300mm | 2KW | AC220/380V 50-60Hz | ≤±0.5% | ||||||

4 Heads | 2500*1700*2300mm | 2KW | ||||||||||

6 Heads | 3500*1700*2300mm | 2KW | ||||||||||

8 Heads | 4500*1700*2300mm | 2.5KW | ||||||||||

Machine Detail

Applications

Machine Details

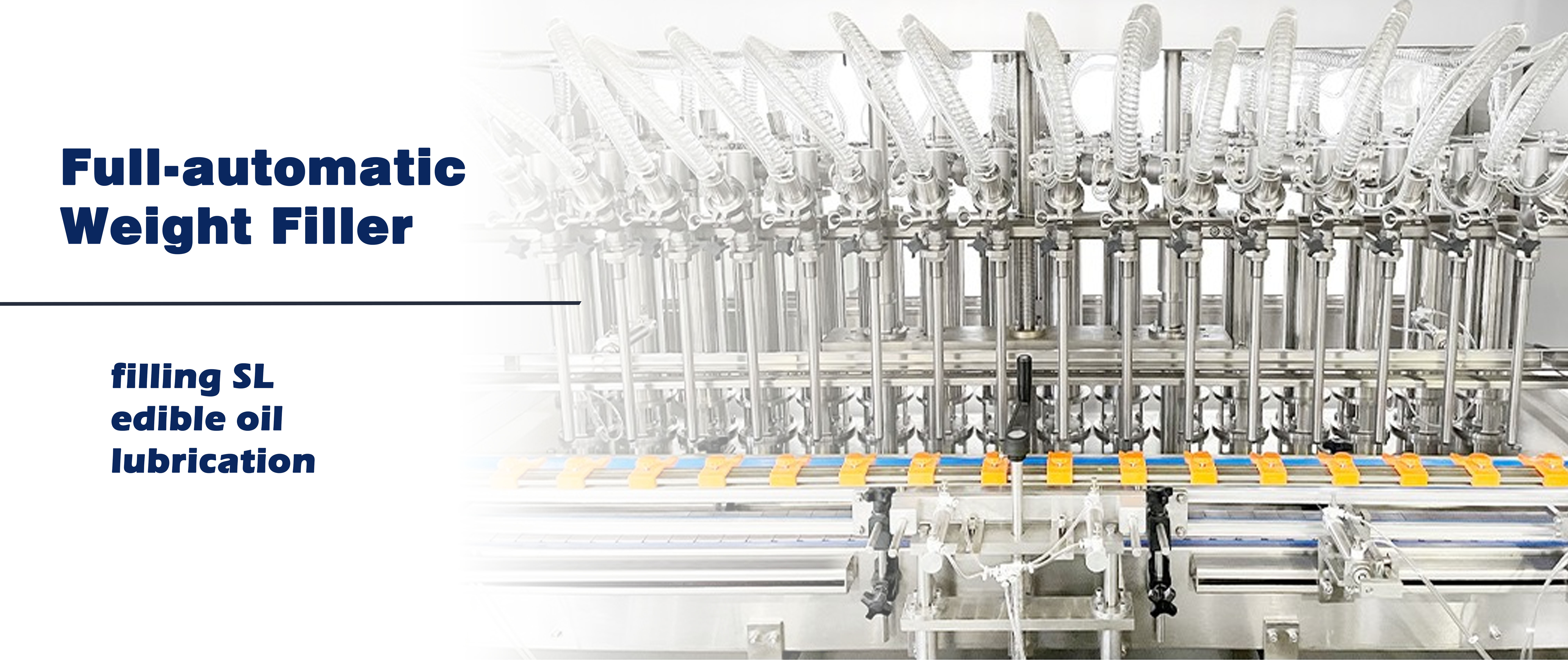

Full-automatic Weight Filler

1. Each filling head has the weigh and feedback system, each filling head can be regulated.

2. This type filler adopts PLC to control, touch screen control panel.

3. It applies dive method to fill and it reduces foam.

4. It automatically achieves counting inlet bottle, gravity filling, and bottle outlet. It is especially good for filling SL, edible oil and lubrication. It is a nice choice for foodstuff pharmacy, cosmetic and chemical industries. 5. Each filling head has the weigh and feedback system, each filling head can be regulated.

6. Photoelectric sensor, approximate switch and other electric elements are of the international famous brands. It ensures no container miss filling. The host machine will alarm if there is any container blocked.

Main Configuration | ||||||

No. | Name | Place of origin | Brand | |||

1 | PLC | Japan | Mitsubishi | |||

2 | Weight Sensor | Germany | HBM | |||

3 | Angle seat Valve | Taiwan | AIRTAC | |||

4 | Solenoid Valve | Taiwan | AIRTAC | |||

5 | Photo Sensor | Germany | SICK | |||

6 | Touch screen | Japan | WEINVEIW | |||

7 | Diving cylinder | Taiwan | AIRTAC | |||

8 | Power button | France | Schneider | |||

9 | Button | France | Schneider | |||

10 | Magnetic switch | Taiwan | AIRTAC | |||

11 | oil-water separator | Taiwan | SHAKO | |||

Filling Head

Advantage: 1.All pipe use quick-change connector 2.Height and space between filling heads can be changed quick and easy to operate

Full-automatic Single-head Capping Machine

1. This is Linear Capping machine running with conveyor automatically. 2. This filling machine is a high-tech filling equipment controlled by microcomputer PLC programmable, equip with photo electricity instruction and pneumatic action. 3. Accurate measurement: adopt servo control system. 4. Bottles will be fixed by two cylinders and it can automatically arrange lid, taking lid and sending lid, it will grasp lid then capping under control of double-acting cylinder lifting stroke. 5. The machine grasp lids through pneumatic type, lid-revolving head has a clutch to ensure the tightened lid not to damage.

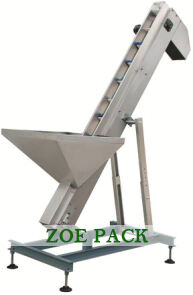

Automatic Lid-sender

The machine is specially used in lifting lid to the lid-revolver for lid-revolving, is an auxiliary equipment of the lid-revolver. If making a few modifying, may be used in lifting and conveying of other hard objects, realizing one-machine multistage.

Exhibition and Certificate

FAQ

|

ZOEPACK

Brings you the best Automatic Linear Chili Sauce Tomato Sauce Paste Filler Plastic Jar Bottle Piston Filling Machine Packing Line. This incredible machine is the perfect solution for those who are looking for a reliable and efficient way to fill plastic jars and bottles with sauces and pastes.

This filling machine is good for high-speed production lines have real profit fill up to 200 containers each and every minute. It really is made to be effortless to work with and keep, with a interface this is certainly user-friendly allows operators to easily adjust settings and monitor the filling process.

The equipment is made out of top-quality materials to make sure dependability and durability, which makes it well suited for use within busy production facilities. It features a fully-automatic linear design, this implies once it is set up and running that it needs minimal operator intervention.

The filling device also includes a piston system this is certainly filling which ensures accurate and consistent filling of every container. This method is specially created to manage dense and sauces that are viscous pastes, ensuring they are filled accurately and without spills.

The Automatic Linear Chili Sauce Tomato Sauce Paste Filler Plastic Jar Bottle Piston Filling Machine Packing Line is also versatile, allowing it to be properly used having a variety is wide of container shapes and sizes. This may make it well suited for use within a variety of different companies, including food and beverages, cosmetics, and pharmaceuticals.

Why wait any longer? Invest in the best and see the difference in your production process with ZOEPACK's Automatic Linear Chili Sauce Tomato Sauce Paste Filler Plastic Jar Bottle Piston Filling Machine Packing Line.