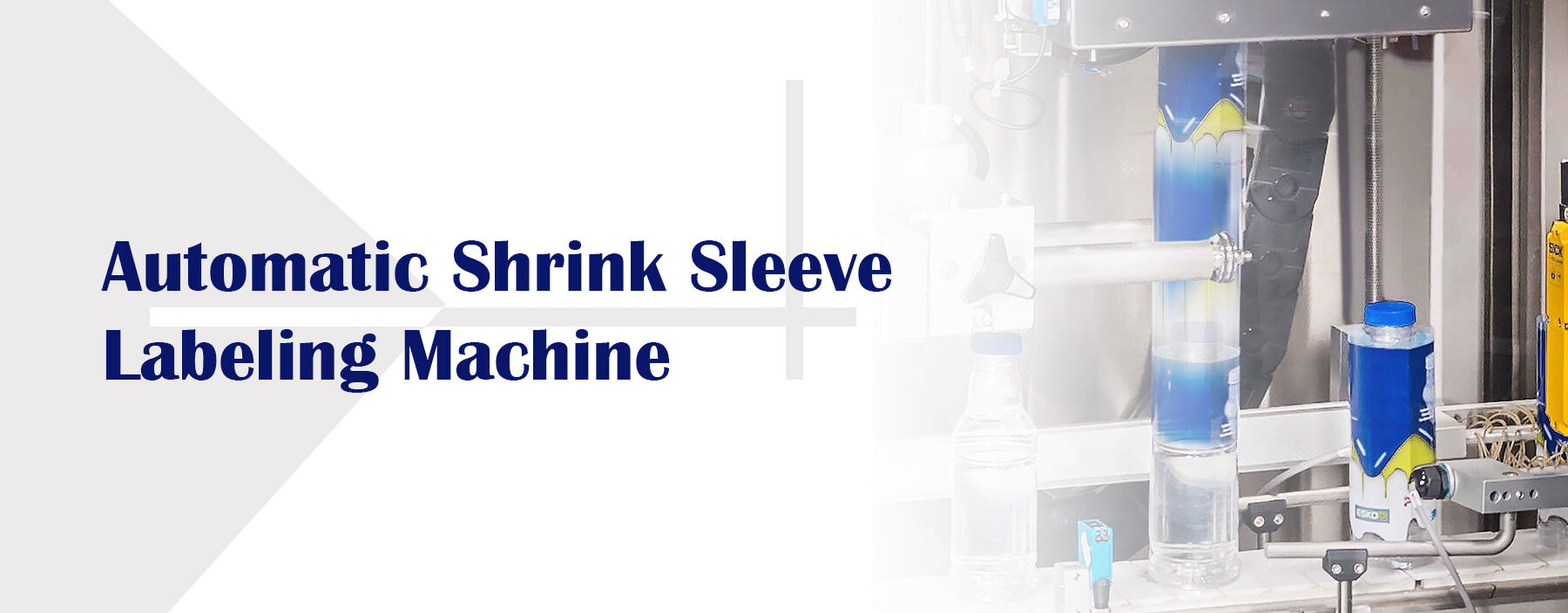

Automatic Shrink Sleeve Labeling Machine /

Automatic Double Head Shrink Sleeve Labeling Machine

● Single Head and Double Heads Shrink Sleeve Labeling Machine

● Automatic Shrink Sleeve Labeling Machine For 5 Gallon Bottle Cap

● Vacuum-grip cylinder and cutting unit adopt special materials which are wearproof and heat protection.

Machine Advantages

1.Automatic Shrink Sleeve Labeling Machine

2.Automatic Double Head Shrink Sleeve Labeling Machine

Features:

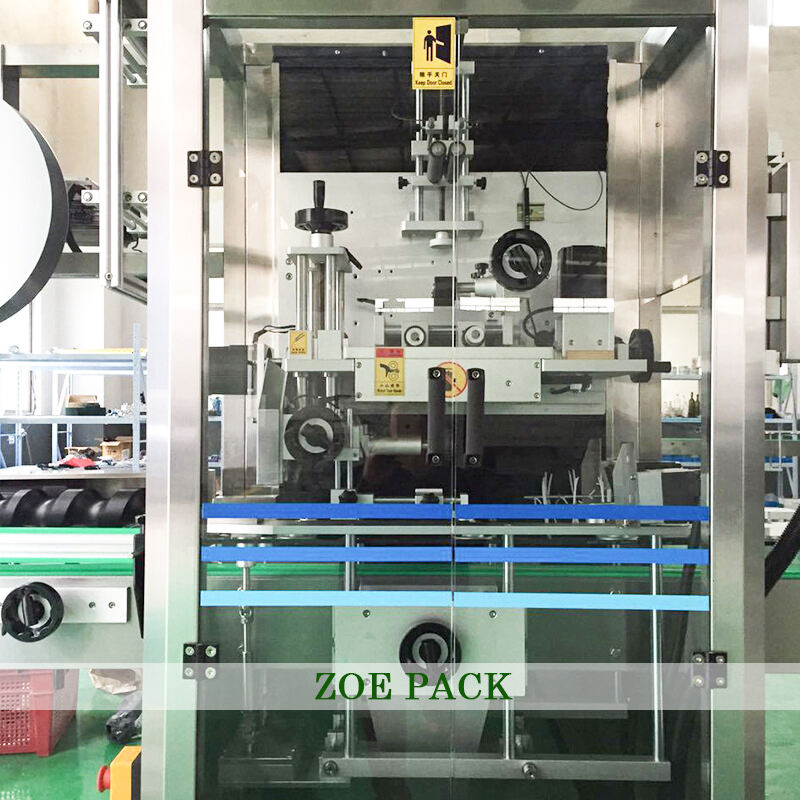

1. According to the characteristics of the trapping label machine,we make improvement from the aspects of mechanical structure, circuit design,and intellectual control to improve the production efficiency. It can satisfy the demands of various beverage manu-facturers as reduce the production cost for the clients and improve the production rate.Because of the design of the equal velocity ratioJt completely realizes the goals of accurate label, smooth label operation and swift label cutting.

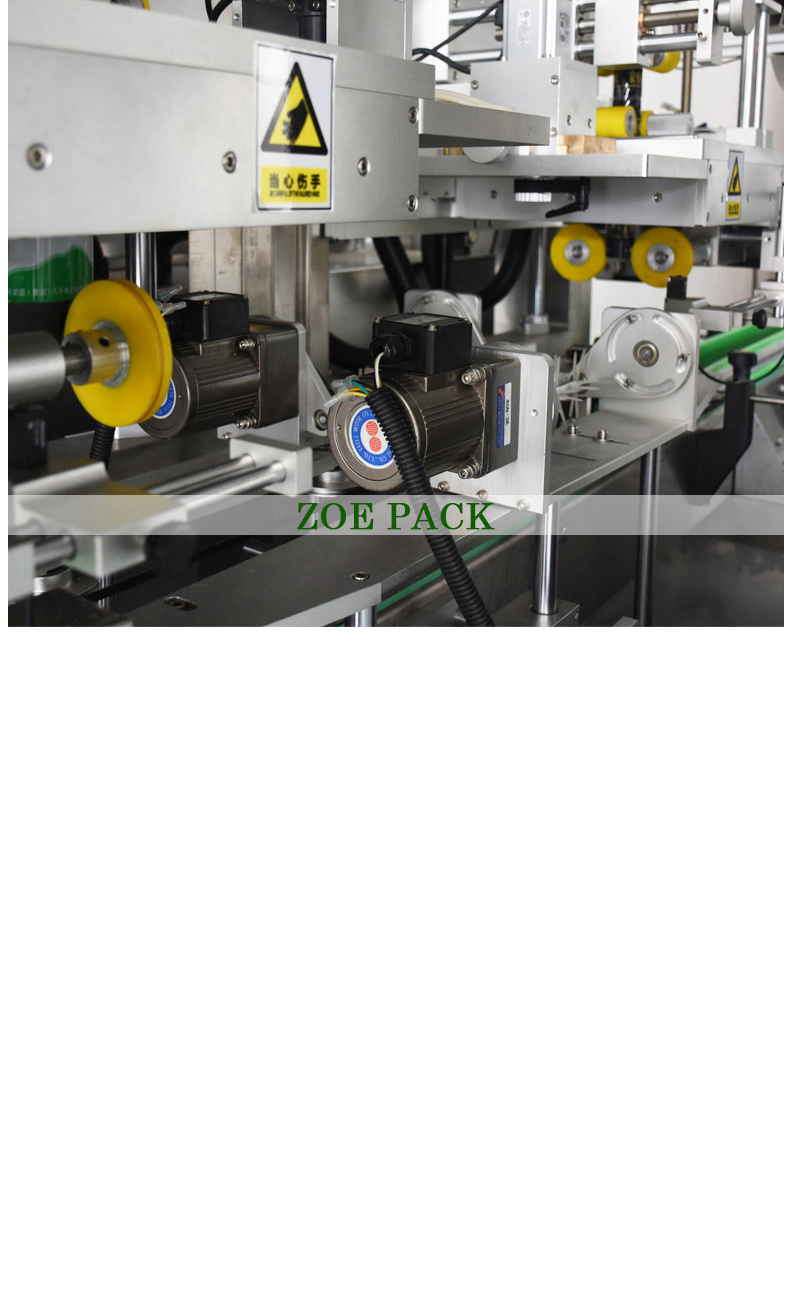

2. This machine uses large quantities of aluminum and high strength, the corrosin-resistant stainless steel, so that the overall structure of the machine more durable and it’s performance is more modular, user-friendly design makes the adjustments more easily and change style much simpler. Using the man - machine interface In the control ststem, which is easy to learn and under-stand.

3. One machine for two purposes, reducing one sleeve labeling machine, saving costs; reducing the number of conveying lines Length or avoid secondary handling, improve production efficiency and equipment area; reduce Reduce process bumps, etc., and improve product quality.

Machine Detail

Product Parameters

Automatic Shrink Sleeve Labeling Machine | ||||

ZP-150 | ZP-250 | ZP-300 | ZP-400 | |

Input Power | 2.5 KW | 3.0 KW | 4.0 KW | 4.0 KW |

Input Voliage | ∮3380/220 VAC | ∮3380/220 VAC | ∮3380/220 VAC | ∮3380/220 VAC |

Production Etticiency | 150 bottles / min | 250 bottles / min | 300 bottles / min | 400 bottles / min |

Size of Host Machine | 2100L*850W*2000H | 2100L*1100W*2000H | 2600L*1100W*2200H | 2600L*1100W*2200H |

Bottle diameter | 28 mm~120 mm | 28 mm~120 mm | 28 mm~120 mm | 28 mm~120 mm |

Length of Label | 30 mm~250 mm | 30 mm~250 mm | 30 mm~250 mm | 30 mm~250 mm |

Thickness of Label | 0.03 mm—0.13 mm | 0.03 mm—0.13 mm | 0.03 mm—0.13 mm | 0.03 mm—0.13 mm |

Paper tube diameter | 5”—10(Free adjustment) | 5”—10(Free adjustment) | 5”—10(Free adjustment) | 5”—10(Free adjustment) |

Automatic Double Heads Shrink Sleeve Labeling Machine | |

Input Power | 6KW |

Input Voltage | ∮3380 / 220 VAC |

Production Etticiency | 2*150 bottles / min |

Size of Host Machine | 3200Lx 1200Wx 2070H |

Bottle Diameter | 28 mm ~ 125 mm |

Length of Label | 30 mm ~250 mm |

Thickness of Label | 0.03 mm — 0.13 mm |

Paper Tube Diameter | 5” — 10(Free adjustment) |

Applications

Related Products

Company Profile

ZOE PACK

ZOE PACK

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery, PET blow molding machine,blow molding machine, injection molding machine, injection blow molding machine, injection stretch blow molding machine during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging machinery, to update the technology, to learn advanced experience, to confirm new theory and new design, we are forming a unique competitive advantage of our owns.

The machines from our company carry good quality and effective after-sales service, upon the market,customers from more than 45 countries, we provide complete solution for your plastic industry business, as well as all sorts of technical support & after-sale services!

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!

FAQ |

|

ZOEPACK

ZOEPACK Automatic Plastic Glass Bottle Aluminum Tins Shrink Sleeve Wrapping Labeling Machine with Steam Tunnel is a versatile and efficient packaging solution that is ideal for modern businesses. This innovative product is designed to streamline packaging processes and boost efficiency, while ensuring high-quality labeling and packaging results.

Features a compact design that saves workspace is valuable without compromising on functionality. The machine was created to meet the requirements of organizations of most sizes, also it is personalized to match packaging is unique.

Many thanks to its automatic procedure, the ZOEPACK Automatic Shrink Sleeve Wrapping Labeling Machine is easy to utilize and requires intervention is minimal operators. The device is equipped with user-friendly touch screen controls that enable staff to monitor and program operations with ease.

Able to handle a wide range of packaging materials, including plastic, cup, and aluminum tins. The machine utilizes a vapor tunnel to make certain that packaging materials are ready for labeling and shrink wrapping. The steam tunnel provides heat consistently ensuring that packaging materials are pliable and simple to utilize.

Built to minimize waste, because of its accuracy labeling and shrink capabilities that are wrapping. This results in price savings for companies, also as reduced impact is environmental.

The ZOEPACK Automatic Shrink Sleeve Wrapping Labeling Machine can be built to final in addition to its impressive performance. Made from durable materials and featuring components that are top-quality, this machine is made to stand up to the needs of modern packaging environments. Which means that businesses can depend on it to provide results that are consistent day in and day out.

Why wait? Invest in the ZOEPACK Automatic Shrink Sleeve Wrapping Labeling Machine today and discover what it can do for your businesses.