Hot Glue OPP Labeling Machine

Major features and performance:

● The change-over of spare parts can be finished within 10 minutes.

● The position of cutting blade can be quickly and accurately adjusted by manual control cabinet.

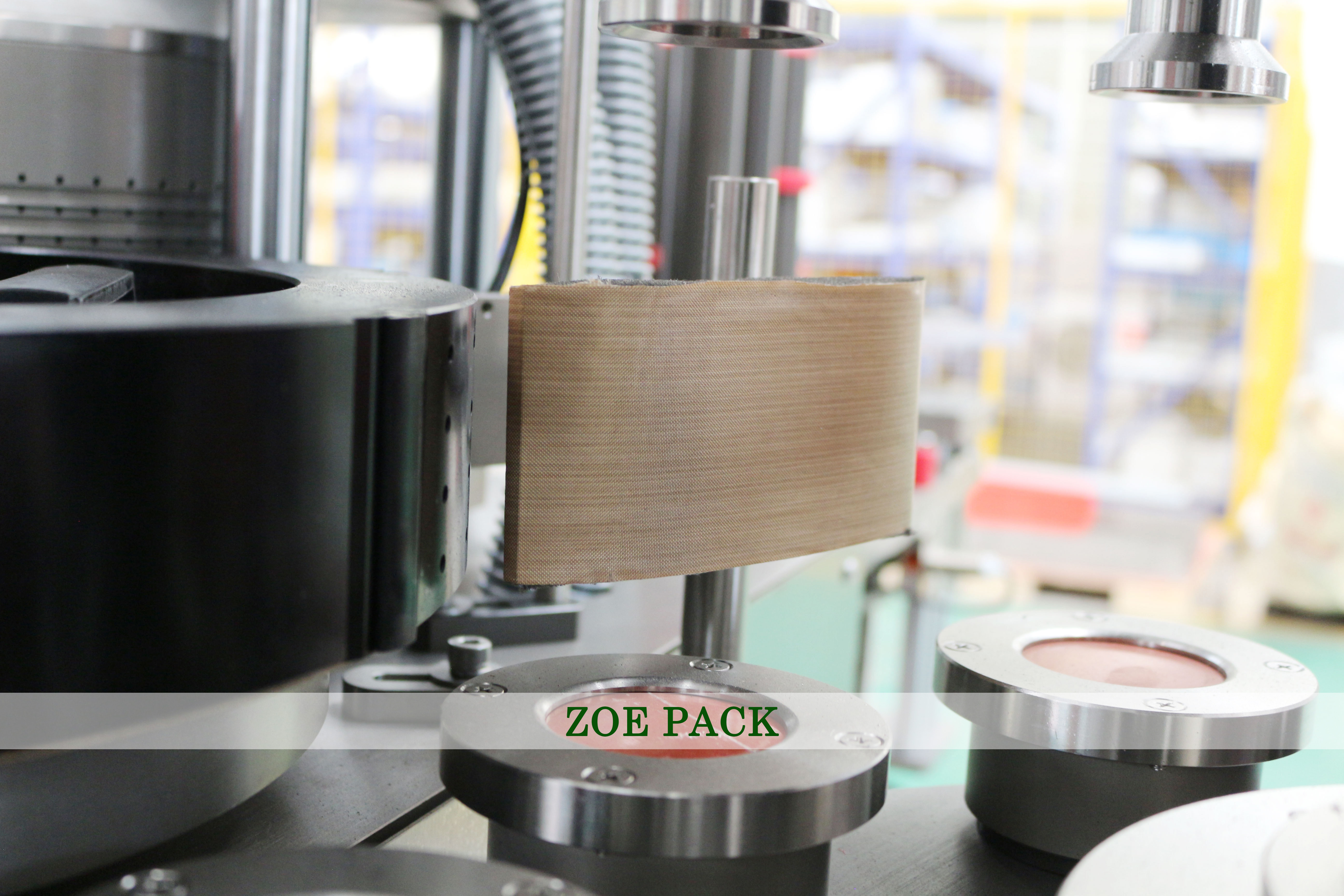

● Vacuum-grip cylinder and cutting unit adopt special materials which are wearproof and heat protection.

Machine Advantages

1.Linear Type Hot Glue OPP Labeling Machine

2.Rotary OPP Hot Glue Labeling Machine

Features:

1. The adjustment of label cutting blade is easy and simple.

2. Vacuum-grip cylinder is made of high hardness material, the additional old handler can reduce the frictions of labels and prevent static electricity.

3. The self-adjustment knob can reset the l-MARK position while change the cutting length of labels.

4. Label type: OPP label in rolls

Machine Detail

Product Parameters

Linear Type Hot Glue OPP Labeling Machine 9000BPH | |

Production speed | 6000-9000 Bottle / hour |

Labeling acuracy | ±1 mm |

Labeling max width | 120 mm |

Weight | 1500 KG |

Label inner diameter | cp 76.2 mm |

Labei outer dimeter | cp 350 mm |

Outline size | 3000*1500*2000 mm |

Using power | 380 V 50 Hz 8KW |

Rotary OPP Hot Glue Labeling Machine 9000-18000BPH | |

Power Supply | AC380V 50Hz 16KW |

Production Speed | 9000-18000 Bottle / hour |

Labeling Accuracy | ±1mm |

Labeling Max Height | 195 mm |

Labei Paper Core's Inn Dia | Φ76.2 mm |

Label Ext. Dia | Φ400mm |

Overall Size | L2000*W2150*H2100 |

Applications

Related Products

Company Profile

ZOE PACK

Our customers are all around the world.

Vietnam, Australia, Indonesia, Malaysia, Thailand, Sri Lanka, Kazakhstan, Russia, UAE, Saudi Arabia, Malta, Romania, Italy, India,Syria, Ethiopia, Egypt, Sudan, Tunisia, Algeria, Kenya, Nigeria, South Africa, Zimbabwe, Mexico, Guatemala, Ecuador, Colombia,Venezuela, Peru....

We have our own service team in

Saudi Arabia, Colombia, Panama, South Africa ...

ZOE PACK

located in Zhangjiagang city, have more than 18 years' experience in the field of plastic machinery, PET blow molding machine,blow molding machine, injection molding machine, injection blow molding machine, injection stretch blow molding machine during the past 18 years, we always force our energy into new areas of plastic machinery, plastic packaging machinery, to update the technology, to learn advanced experience, to confirm new theory and new design, we are forming a unique competitive advantage of our owns.

The machines from our company carry good quality and effective after-sales service, upon the market,customers from more than 45 countries, we provide complete solution for your plastic industry business, as well as all sorts of technical support & after-sale services!

ZOE PACK will be your reliable friend in China, and we will always do our best to give you max support!

FAQ |

|

ZOEPACK

ZOEPACK Fully Automatic Rotary Hot Melt Glue OPP Labeling Machine for Bottles is the very best machine in its own classification. This labeling machine was created completely; your labeling procedure is quick and effective. The gadget is completely automated, significance it is easy to run along with minimal private treatment. The device's innovation allows the labeling to become accomplished instantly, conserving and enhancing the effectiveness of a company.

Furthermore, the device is extremely easy to use, although the label can easily rapidly be changed and simply. This versatility within the device's labeling procedure implies you can easily utilize it to utilize label in various production circumstances. An extra beneficial possession of using this labeling device is its own level that's almost every one-off. The device was produced to use the label precisely when you take a check out the bottles, getting rid of the possibility of mislabeling. The equipment's originality is because of its own capability to accomplish precision that's higher while labeling at broadband.

The labeling procedure while utilizing the ZOEPACK Fully Automatic Rotary Hot Melt Glue OPP Labeling Machine for Bottles is simple and easy. Bottles are packed coming from the device, and the procedure that's labeling immediately. Labels are supplied in the device using a conveyor belt and thinking about that the bottles goes through the item; the label is put on the compartment adhesive that's utilizing is hot melt. Hot-melt adhesive is an ingenious labeling innovation that guarantees that labels typically don't happen the bottle down.

The devices can be fast allowing it to label as much as 6000 bottles each hr. This price, integrated along with the machine's precision, assists it is ideal for high-volume manufacturing circumstances. Additionally, the devices are developed to label bottles of different forms and dimensions. This flexibility allows the devices to be used in various businesses, like for pharmaceuticals, drink markets, and dishes.

The device is completely automated, significance very little treatment that's private required with the labeling treatment. The device is produced to have actual upkeep that's very little, which reduces downtime. Procedures can easily run efficiently, enhancing effectiveness and decreasing manufacturing sets you back.